Detect smallest height differences

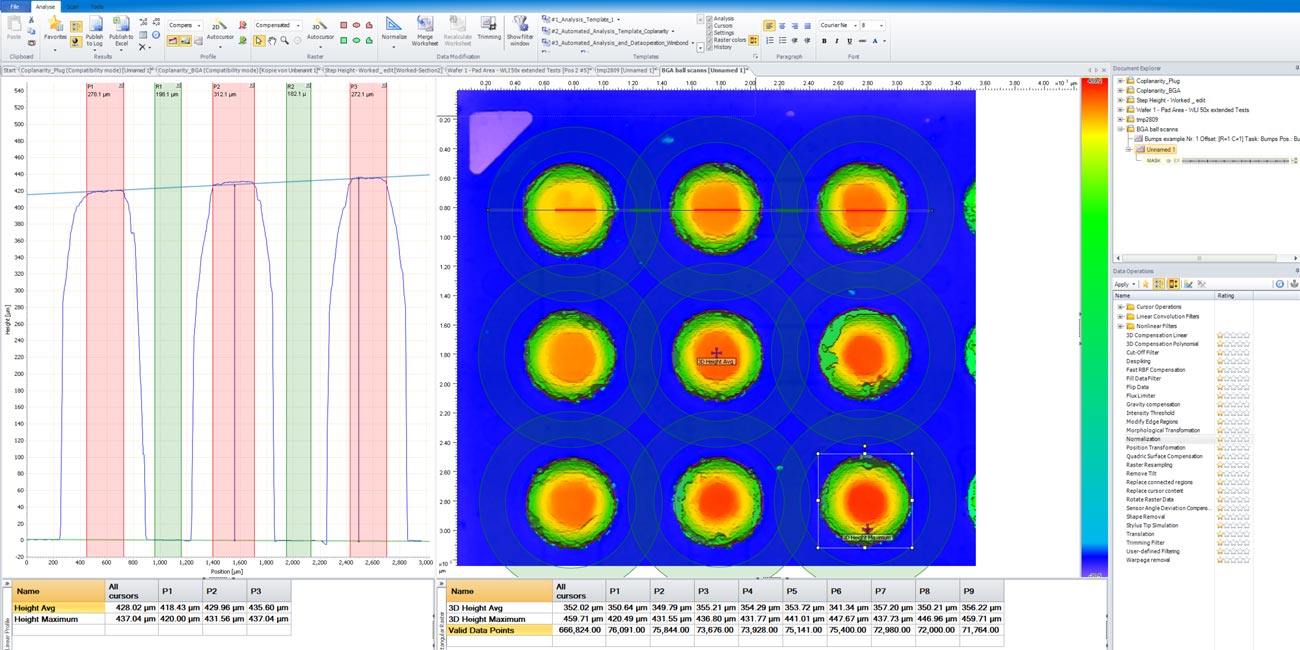

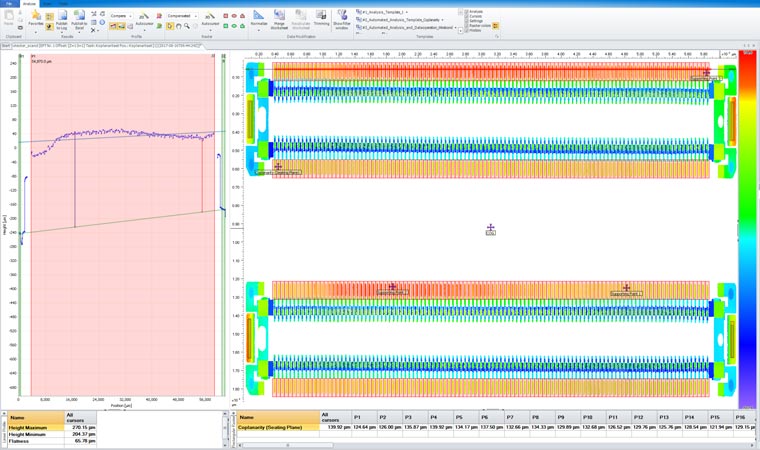

Coplanarity is essential for many products. Accurately measure and analyze bumps, balls (BGAs), pins (PGAs), pads (LGAs), leads, SMDs and other electronic components for coplanarity using a seating or regression plane analysis.

Coplanarity Analysis

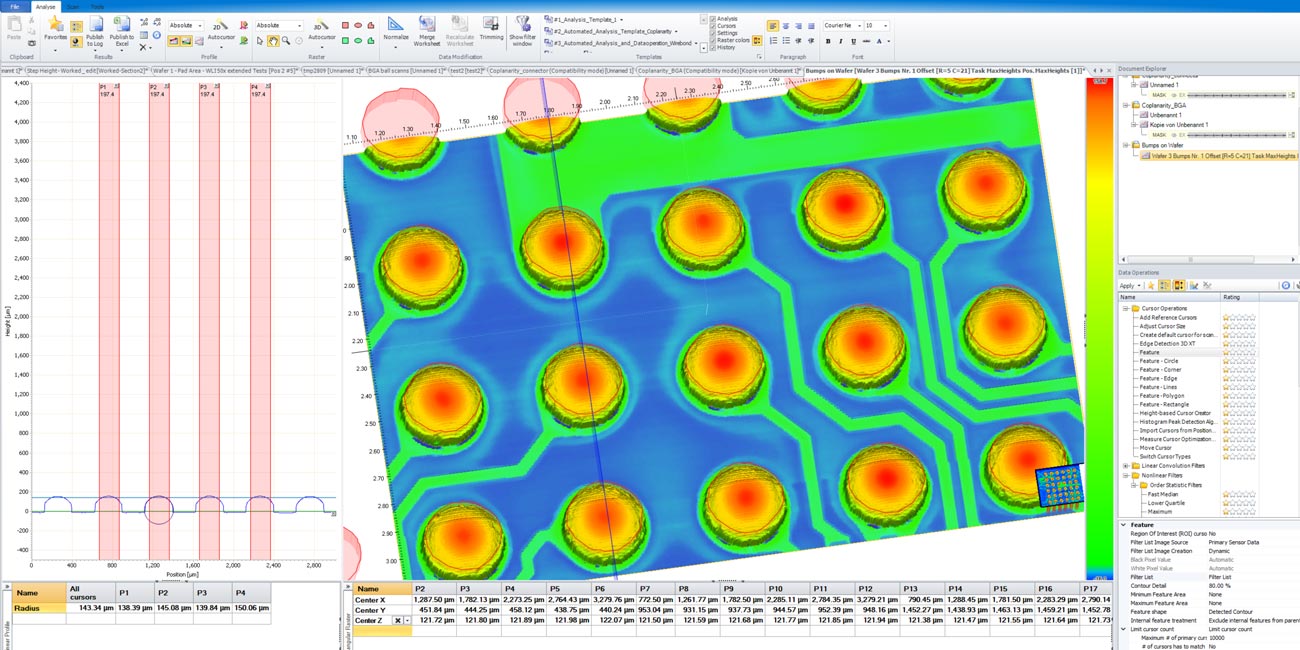

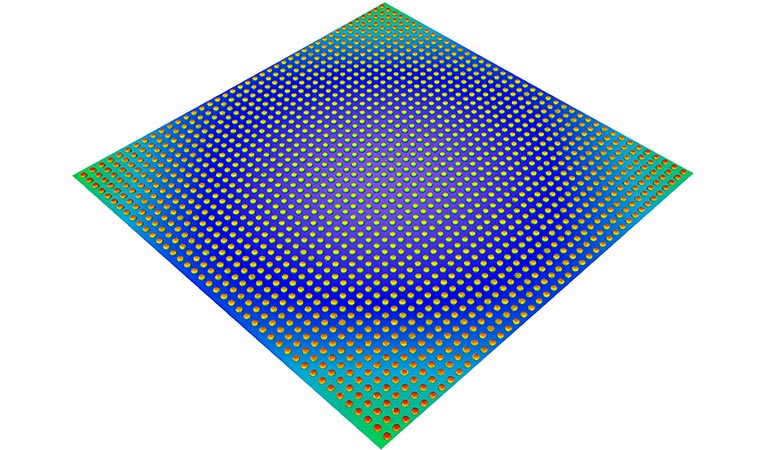

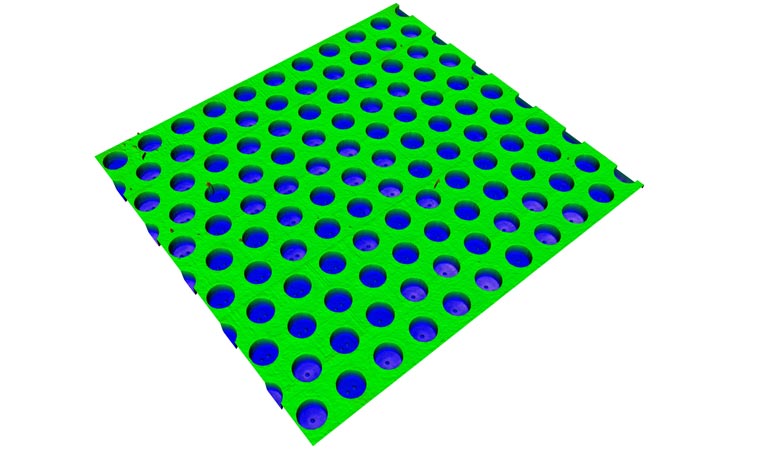

All bumps, leads, pads or any features can be detected automatically based on height, reflectivity or by importing coordinates.

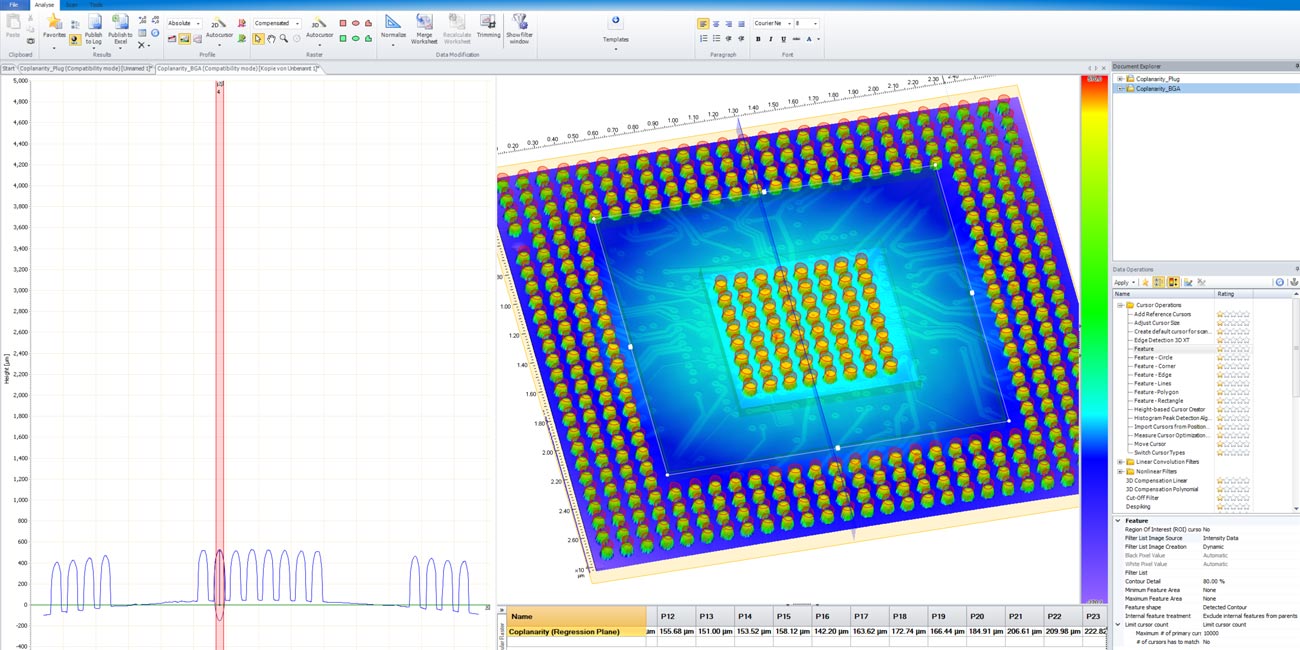

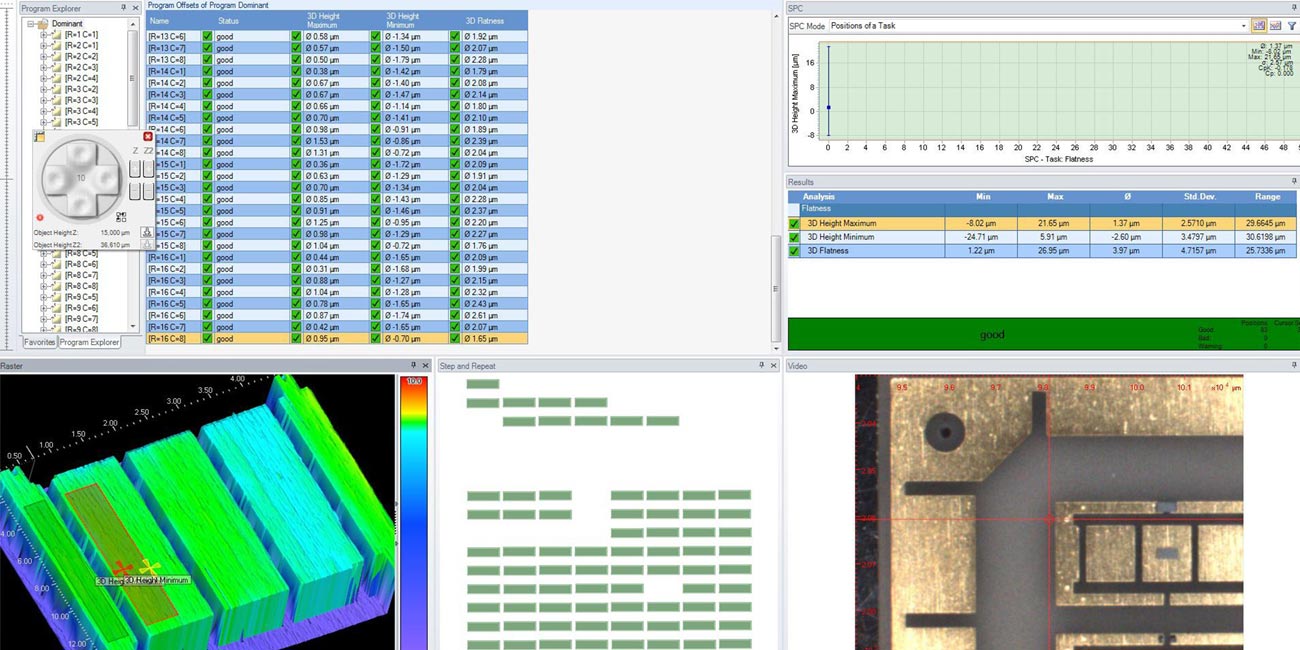

Coplanarity (Regression plane)

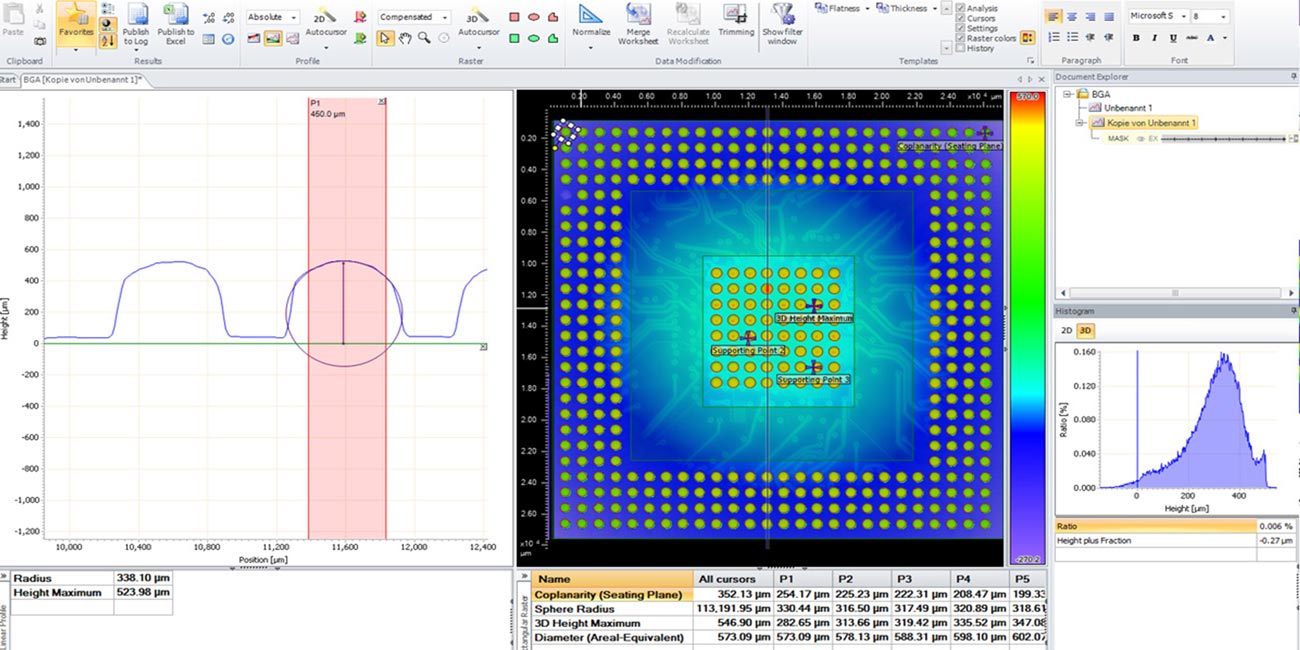

Coplanarity (Seating Plane)

Coplanarity based on the seating plane is calculated by defining a plane created by the three highest points that surround the center of gravity while avoiding intersection with other components. All this is done automatically and the center of gravity can be easily adjusted if needed.

(Local) Height

Position

Automate your Coplanarity measurements with ASCAN

Do you have question about your Coplanarity measurements?

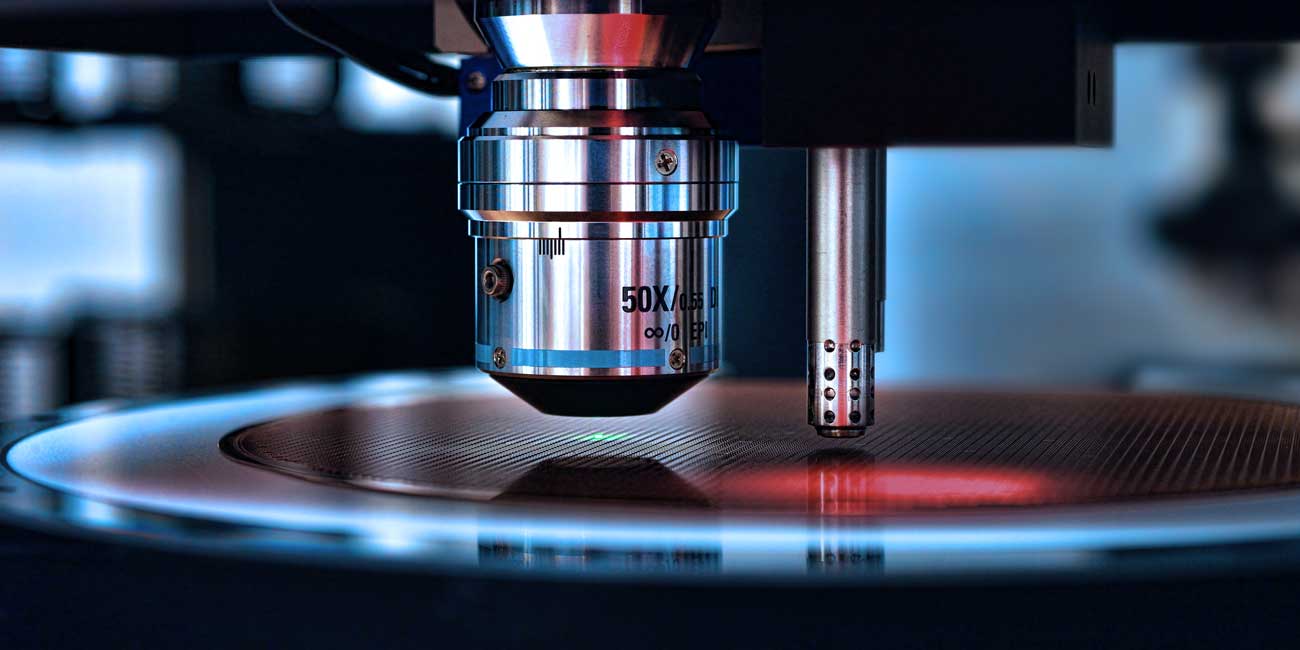

Non-Contact Measurement

Our metrology systems offer a wide range of optical sensor technologies, enabling measurement capabilities at nanometer-level resolution. For coplanarity measurements chromatic confocal sensors, confocal microscopy or white light interferometry can be used.

Chromatic Confocal Sensor

Chromatic confocal sensors capture millions of measurement points per second with Z-resolution as fine as 3 nanometers. They are ideal for coplanarity measurements and work effectively on nearly any material, whether highly reflective or low-reflective. This makes them a top choice for fast, accurate measurements over small and large surface areas.

Confocal Microscope

Measure and analyze small bumps with resolutions down to 1 nanometer. Easily switch between different field of view of views and resolutions using an automatic objective turret for seamless objective changes in manual and automatic mode.

3D White Light Interferometer

White Light Interferometry (WLI) is highly effective for measuring small bumps due to its exceptional Z-resolution, reaching as fine as 0.1 nanometers. This capability allows the WLI to detect minute height variations, which is essential for accurately characterizing tiny bumps and surface irregularities.

Examples

Bumps on Wafer

Pads

Measure the coplanarity of pads efficiently, whether examining the height of individual pads or multiple pads at once.

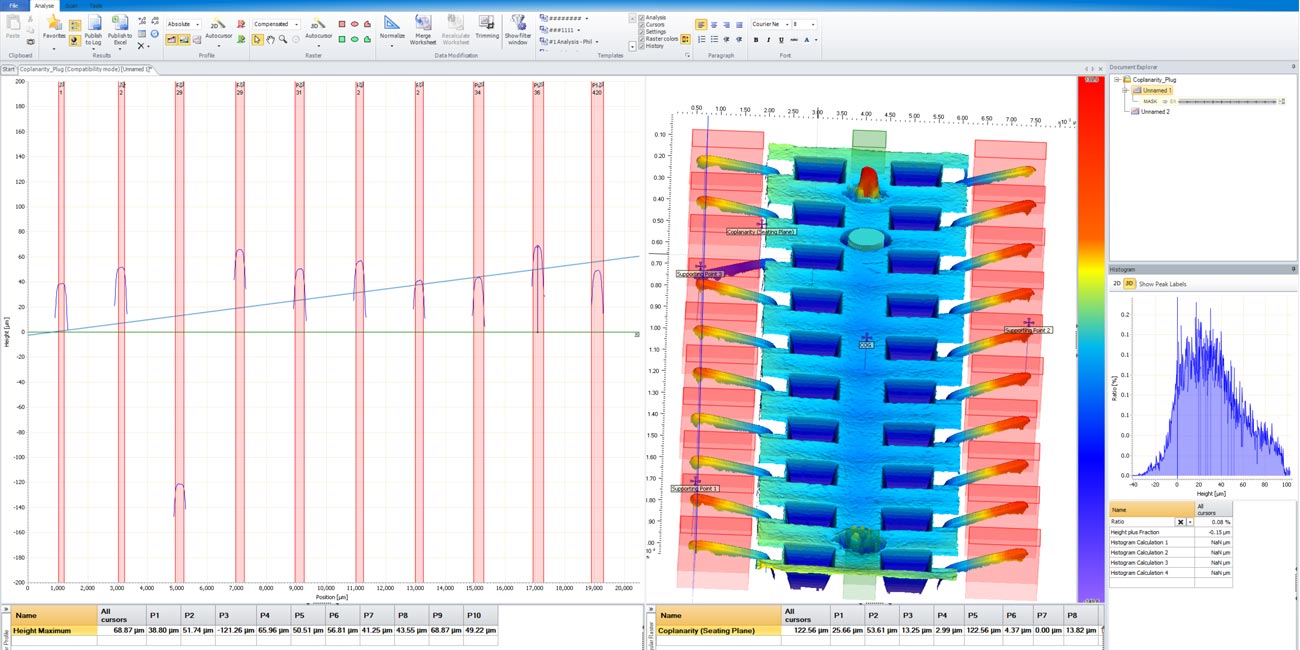

Connectors, Pins

Measure the coplanarity of connectors, whether individually or multiple connectors simultaneously, with the ability to zoom in on each pin as needed for detailed analysis.

Other Applications

Absolute thickness, thickness variations (TTV, LTV), parallelism or compare positions of features from top to bottom surface.

Measure Flatness, Bow, Warp and more of substrates, wafer or any other sample.

Let's discuss your needs to find the best solution for you.

General

cyberTECHNOLOGIES GmbH

Georg-Kollmannsberger-Straße 3

85386 Eching-Dietersheim

Germany