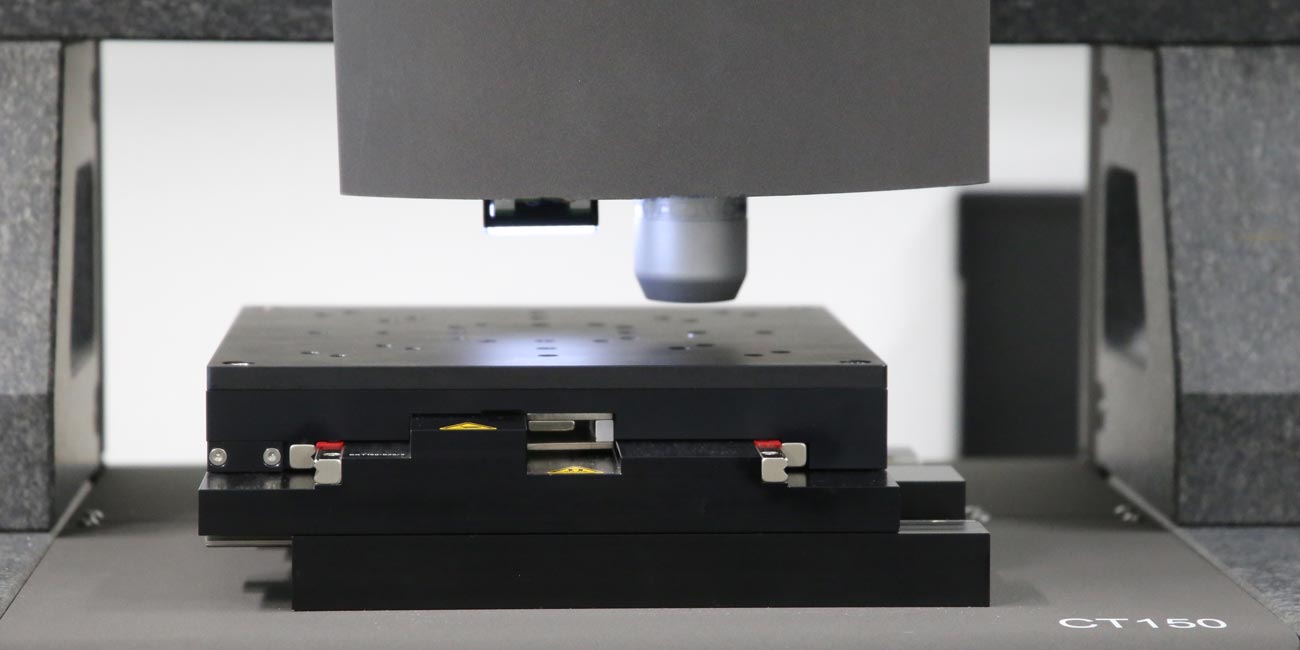

CT 150

Compact Metrology System for R&D and laboratories

Measurement and Analysis Modes

Manual / Automated

Measurement Area

148 x 148 mm²

Example Use-Cases

Substrates, electronic components, wafers up to 6“, other parts and components within measurement area

Advanced Table-Top Metrology

The CT150 is an excellent solution for R&D and failure analysis laboratories. Its adaptable design allows the integration of multiple sensors into a single system, supporting a wide range of applications.

Made to Measure

The CT-Series offers a uniquely versatile platform, designed to seamlessly adapt to a wide range of metrology applications. With customizable configurations tailored to your exact needs, it guarantees precise control over your products and processes.

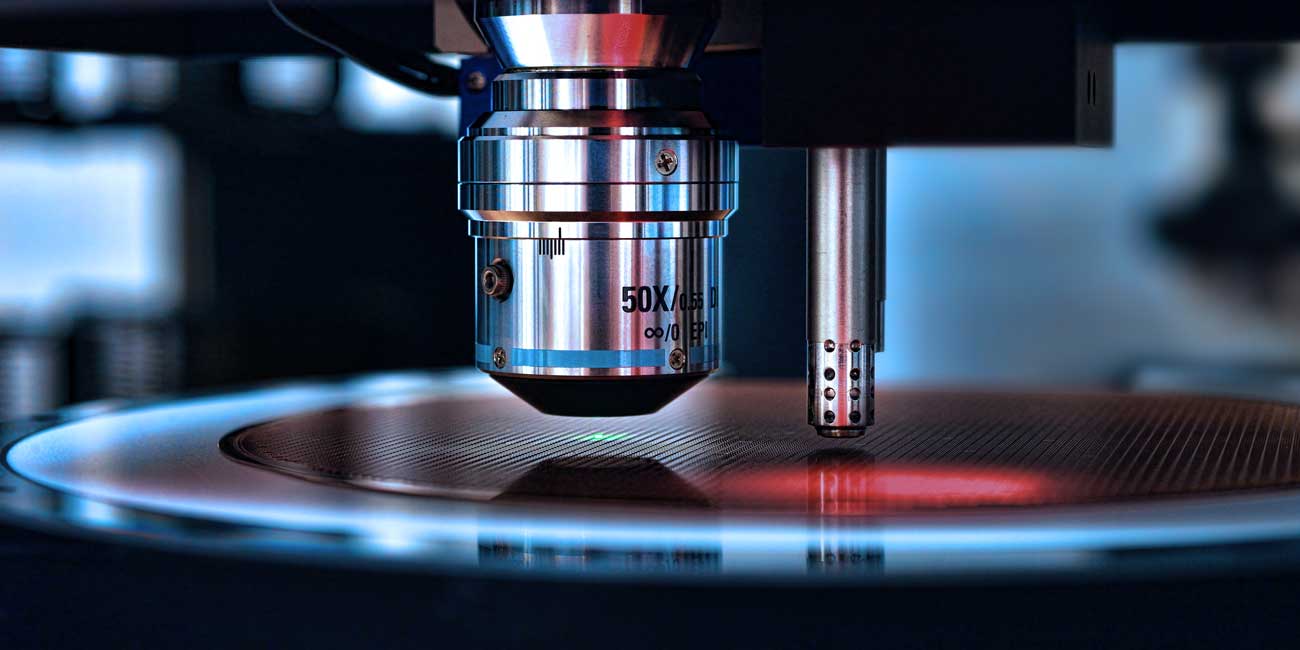

Choose from six different non-contact sensor technologies for high-resolution down to 0.1 nanometer or high-speed measurements with up to 36 million datapoints per second. Add great flexibility with a combination of multiple sensors and objectives in one single system.

The system includes an automated Z-axis for adjusting to different sample heights, offering autofocus functionality and a range extender to measure heights beyond the sensor’s standard range. The Z-axis on the CT 150 is available in 100, 150, or 200 mm sizes.

The X/Y-stage offers 148 x 148 mm² travel with 50 nm resolution for pinpoint sample positioning and lateral measurements. Optionally enhance the stage with a vacuum chuck or sample specific interfaces.

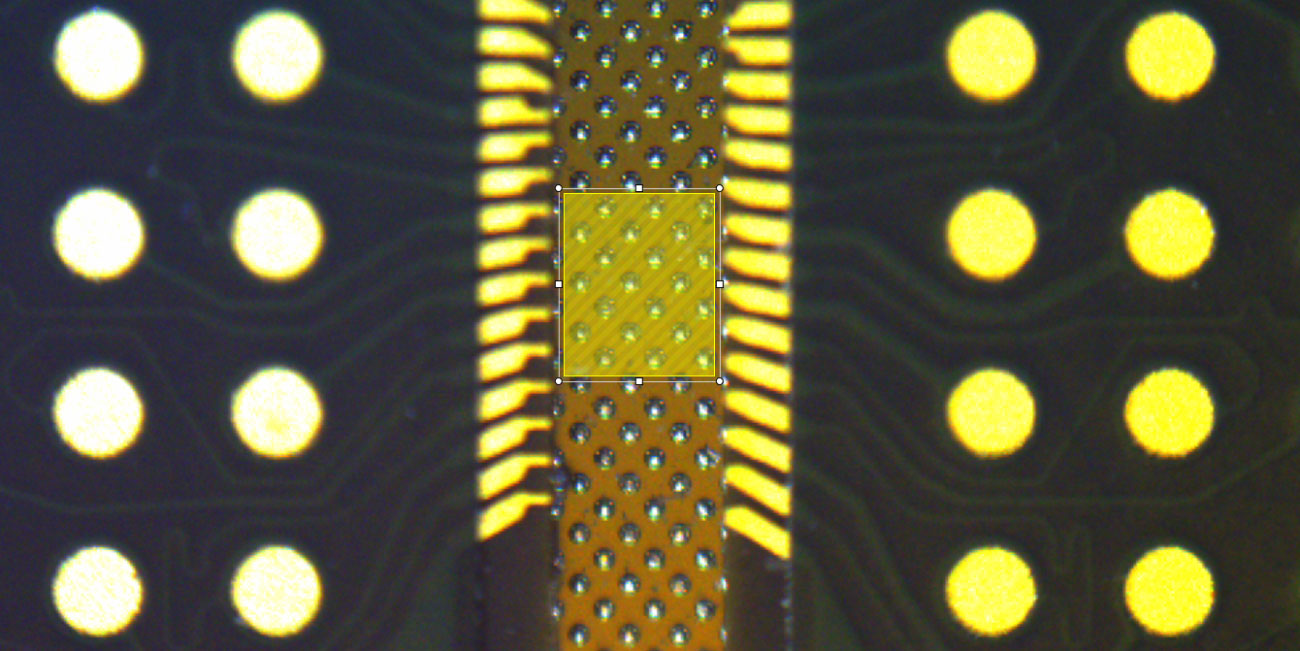

Focus on what matters. The system features a built-in camera with multiple magnification options, allowing you to easily navigate on your samples or choose the sensor’s scanning area in live view. Additionally, the camera enables quick and automated fiducial alignment.

Available Sensors

Flexible high-speed measurements on almost any material with a z-resolution down to 3 nm.

Thickness measurement with a resolution down to 1 nm.

Measure step heights or features with a z-resolution down to 1 nm.

With a z-resolution of down to 0.1 nm for smooth surfaces or smallest (step) heights.

Fast and high-accurate thin film measurement down to 10 nm.

For precise and fast position and lateral measurements with up to 235 MP.

Interested in a configuration of the CT 150?

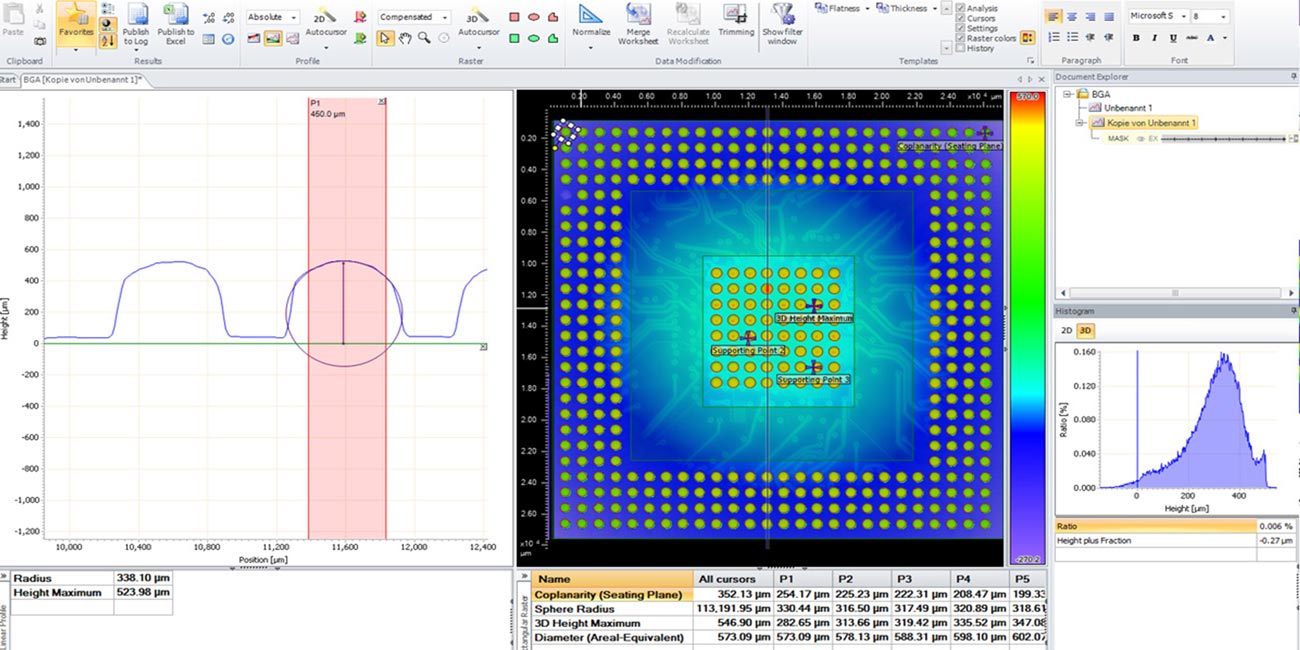

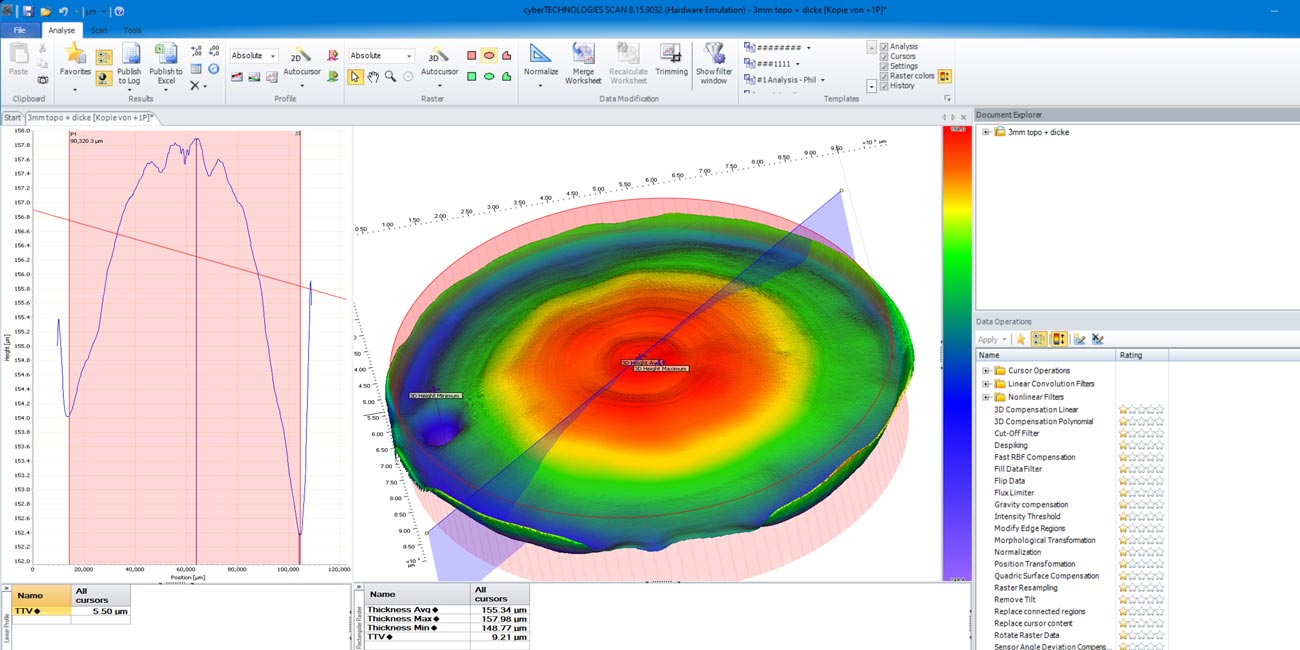

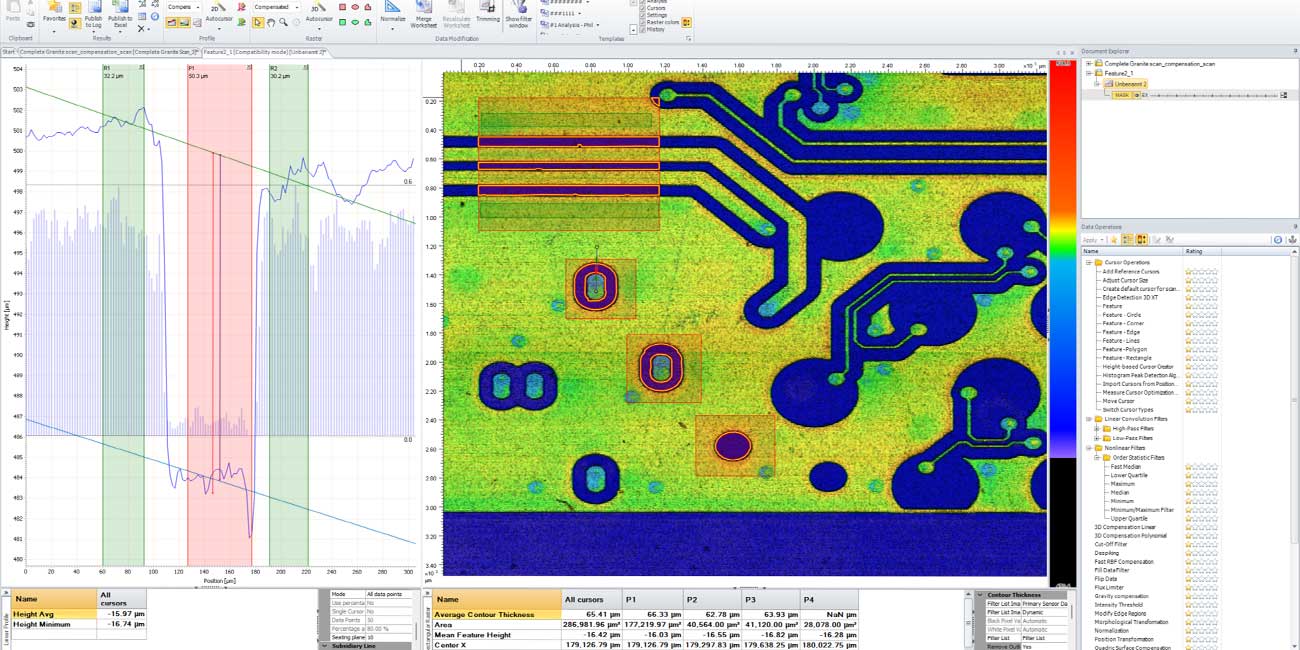

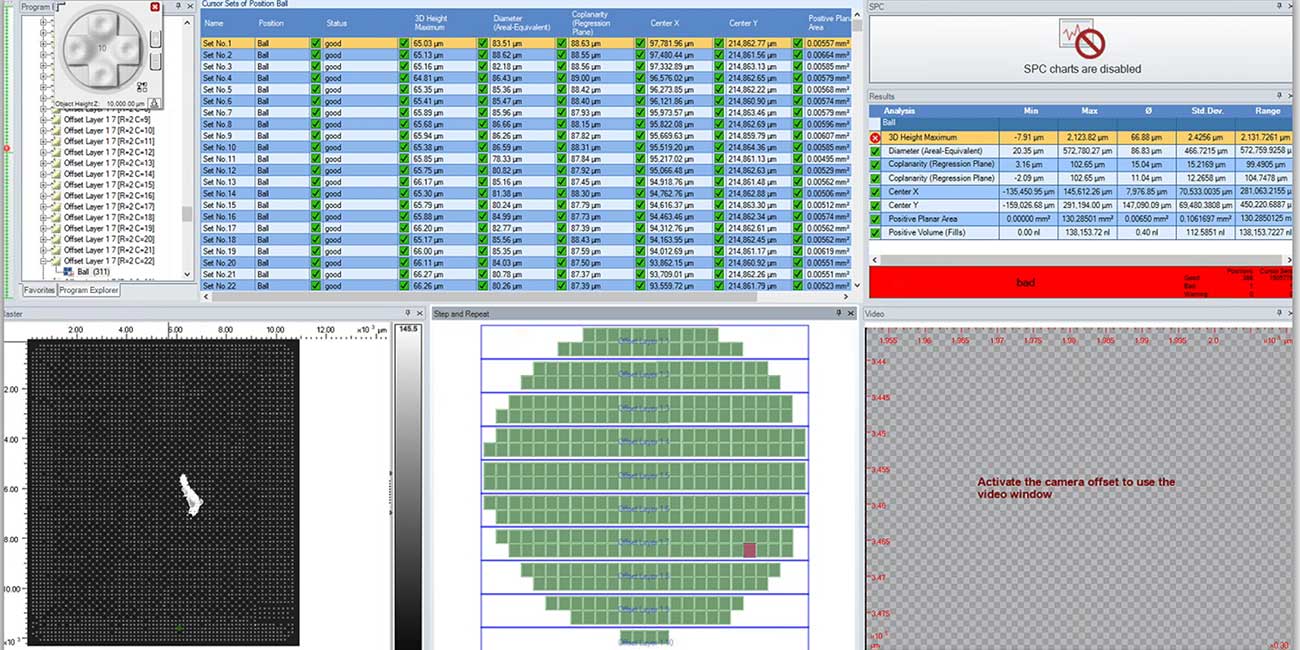

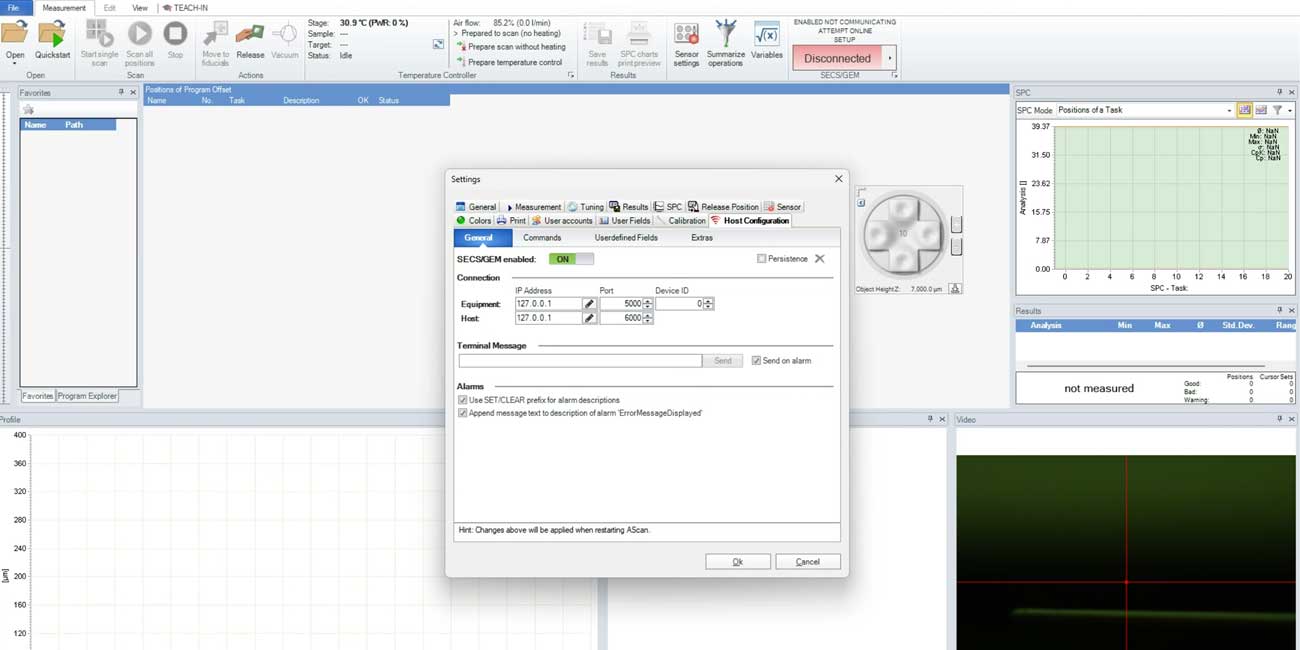

Powerful Analysis

& Automation for Production

Application Examples

The versatile design of the CT-series offers a wide range of applications in production or advanced laboratories.

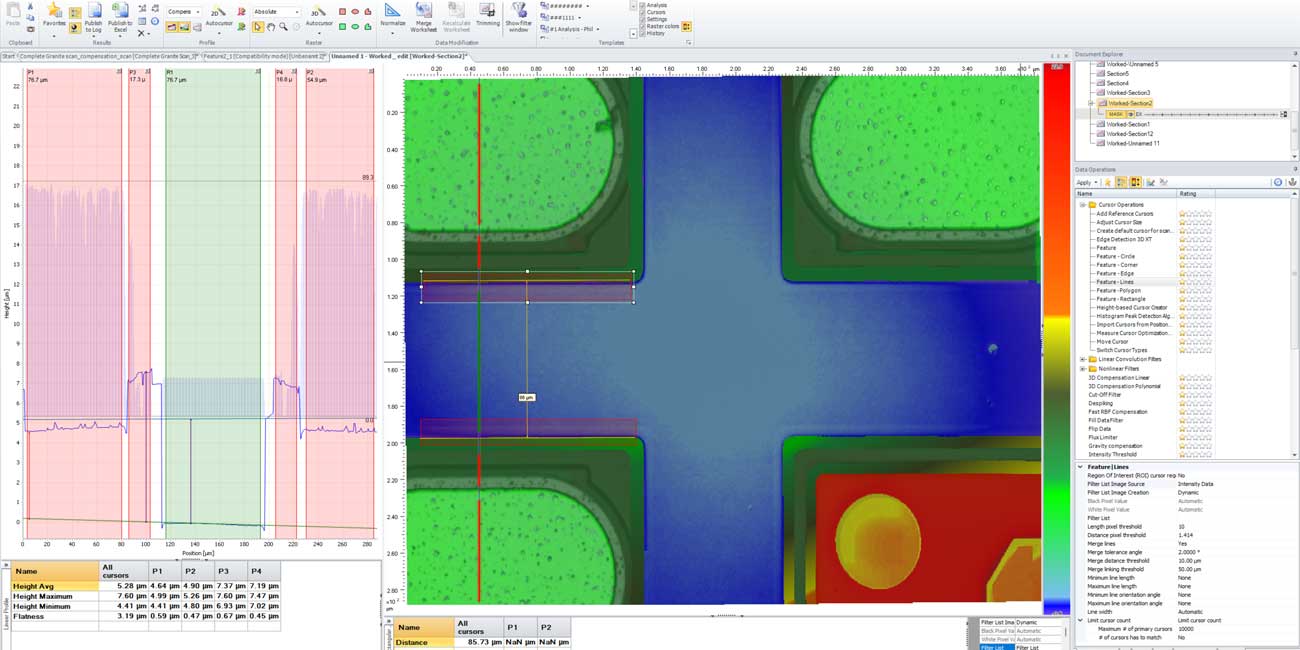

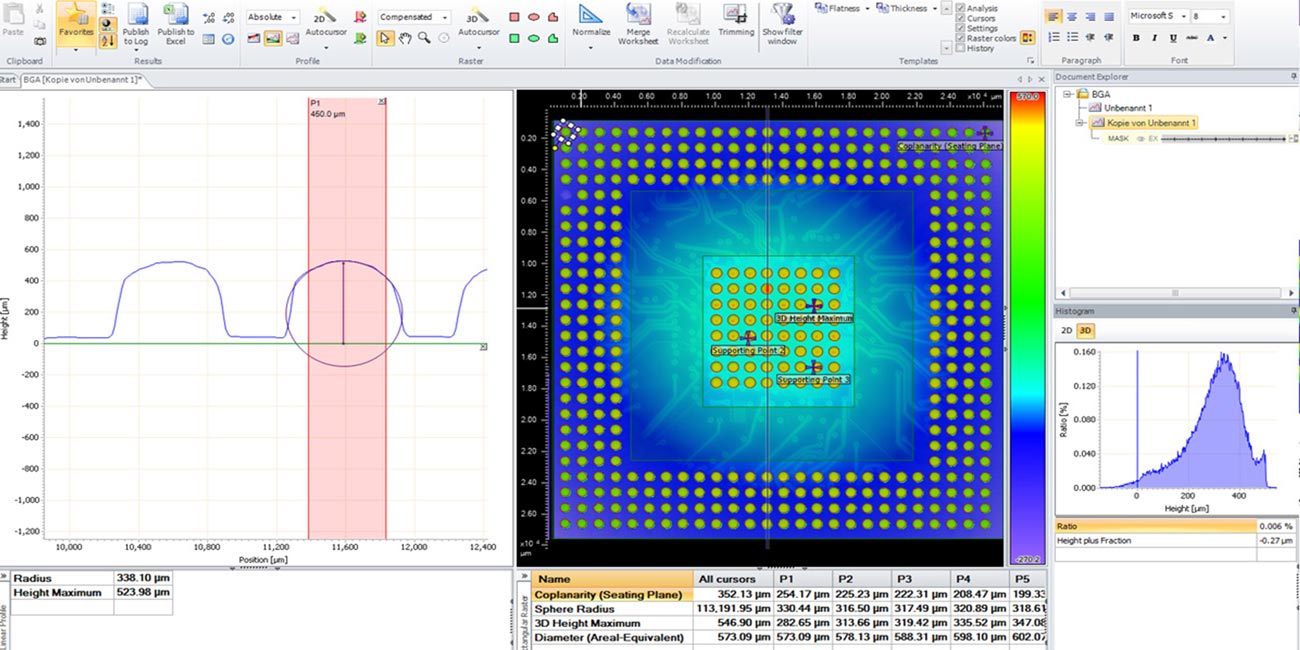

Heights and Critical Dimensions

Coplanarity on bumps, pads, pins or connectors

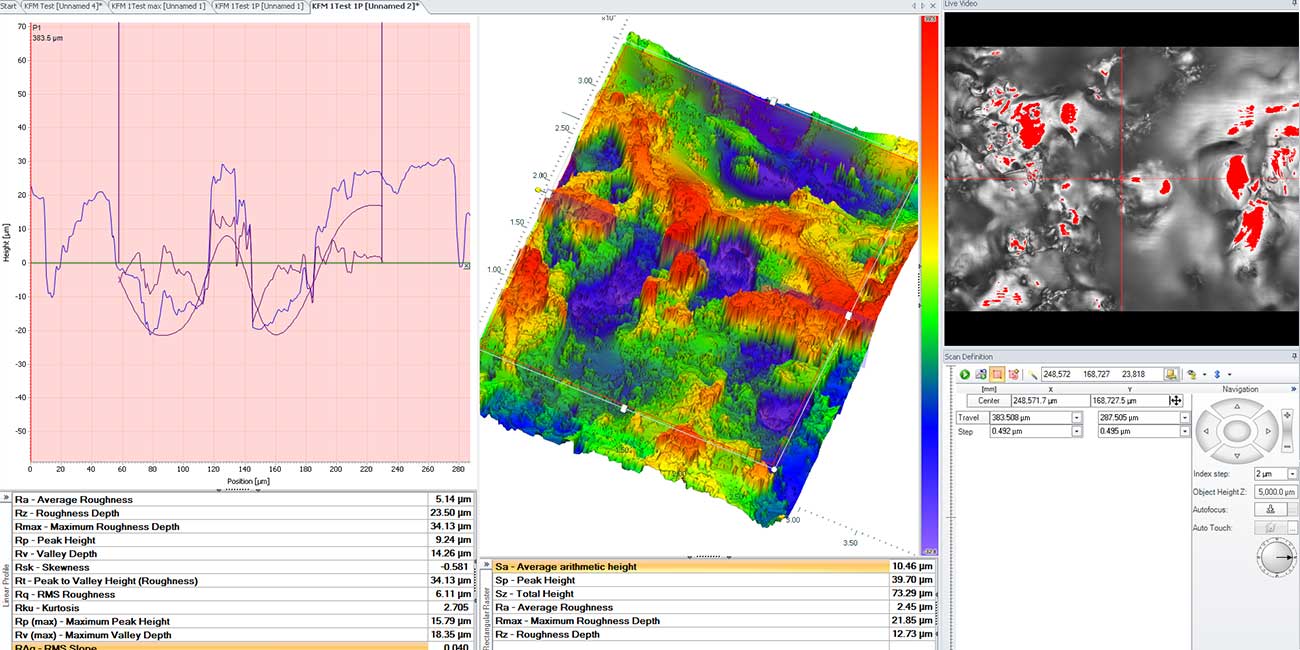

Roughness

Options

The CT 150 can be extended with various options like code readers, (customized) interfaces

Calibration Targets

Calibrate and certify the system anytime with ease. A wide selection of calibration targets and built-in automated procedures make the process fast and easy.

Flexible Interfaces

For secure sample handling, the system can be equipped with software-controlled vacuum chucks available in standard or custom designs, as well as alternative interfaces such as three-point alignment for wafers.

General

cyberTECHNOLOGIES GmbH

Georg-Kollmannsberger-Straße 3

85386 Eching-Dietersheim

Germany