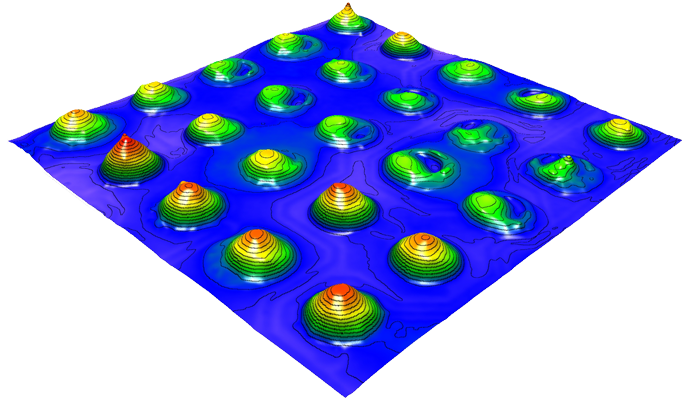

Transparent Films & Coatings

Analyze transparent films, layers and coatings for thickness or heights.

Analyze

Transparent Materials

Our metrology systems enable precise measurement of transparent films and coatings or multilayer films without damaging the material or the need to prepare the sample.

Analysis

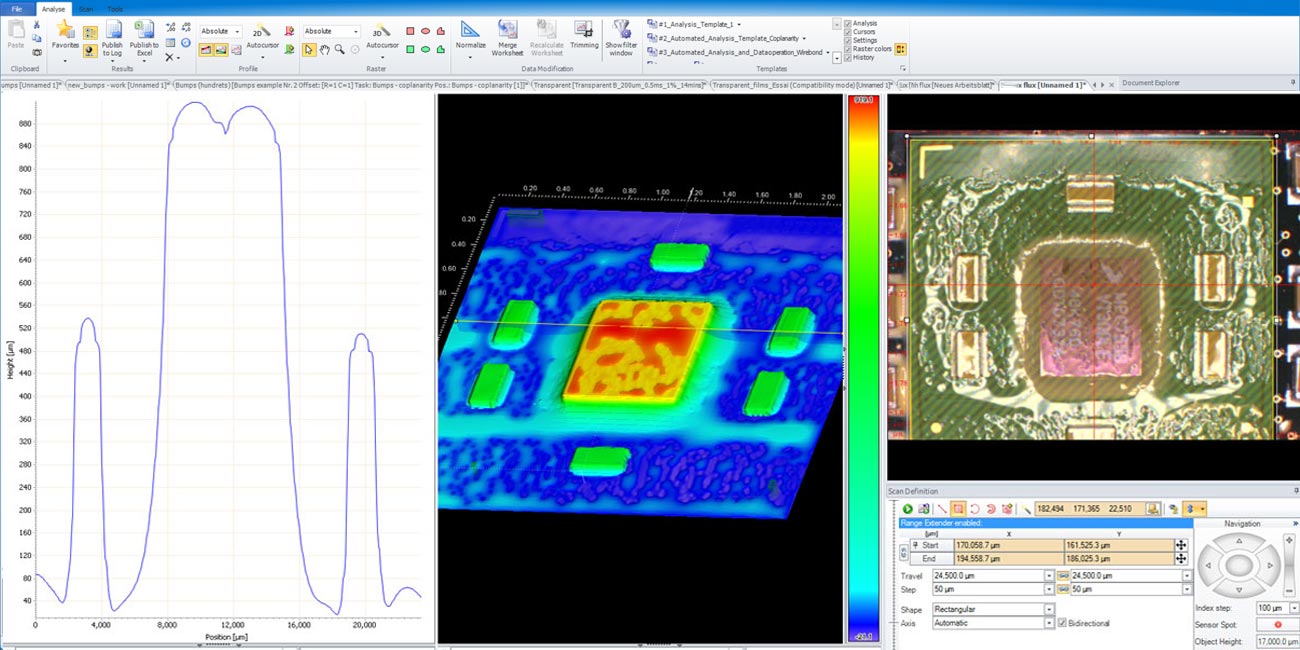

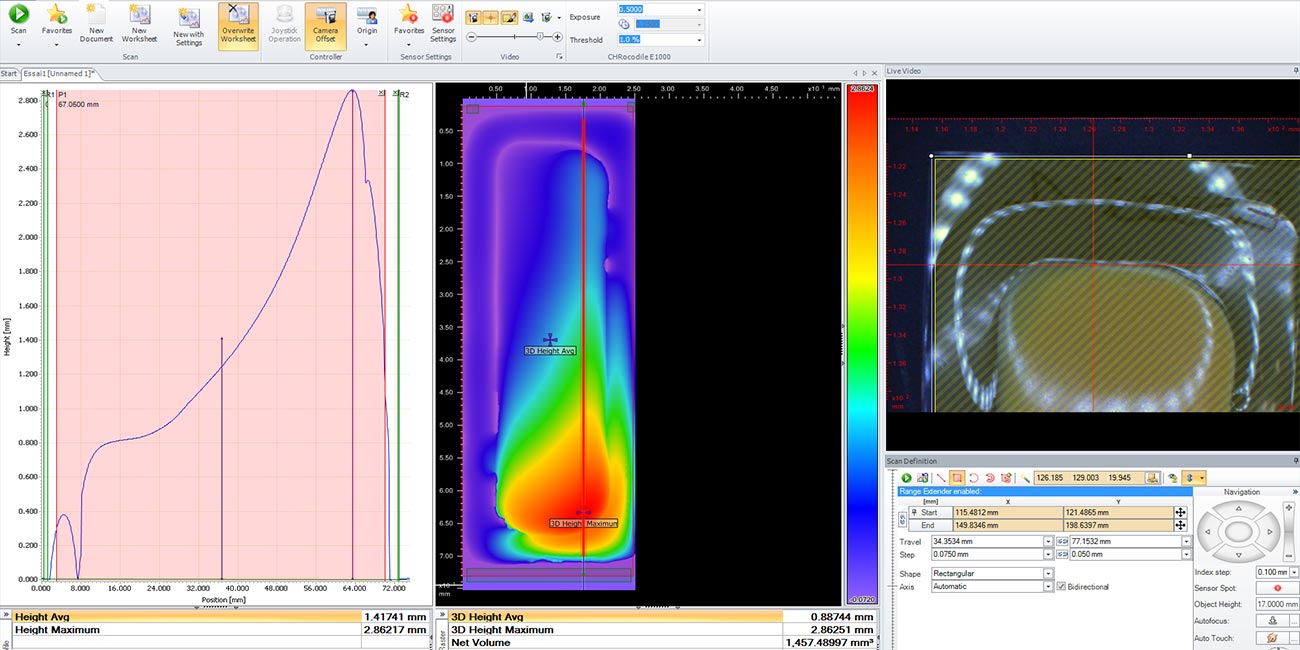

Analyze the thickness or volume of materials such as transparent flux, epoxy or coatings. Perform high-accuracy measurements of multilayer films. Or analyze and measure the surface and height of transparent materials with precision.

Height

Measure height and height differences either on the top of the transparent layer or on the surface beneath it. Simply choose the surface (peak in the sensor settings) you want to measure within the software.

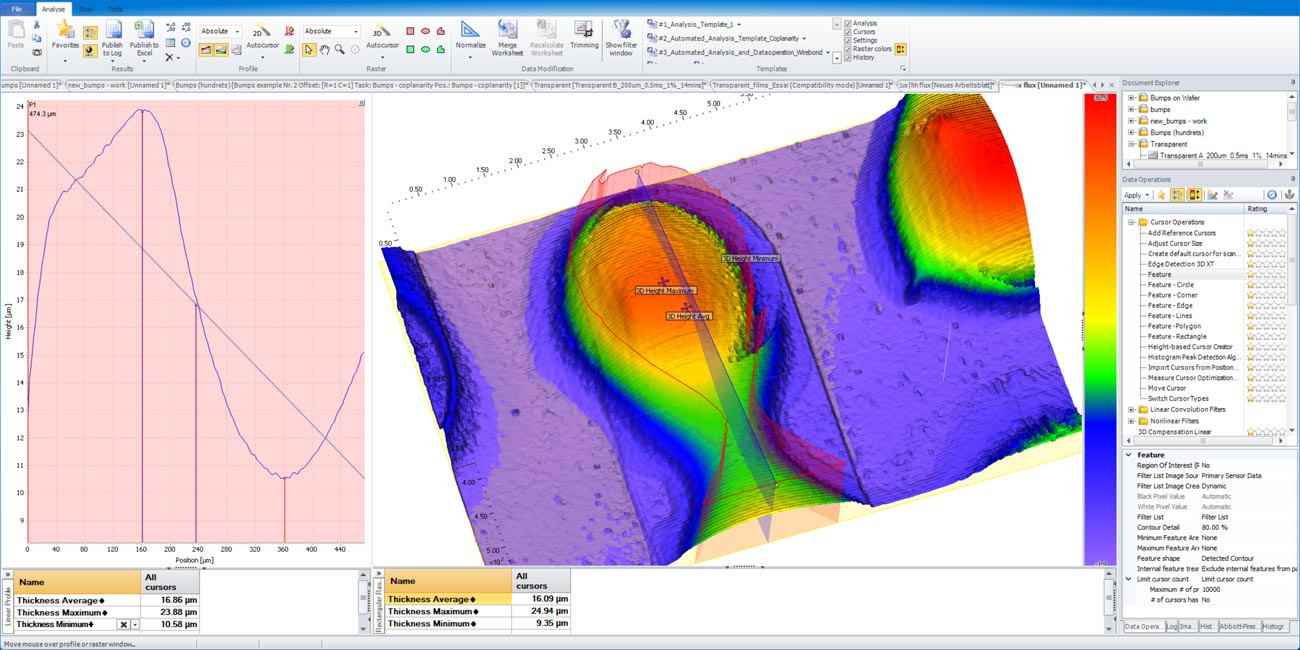

Thickness

Measure thickness measurement of transparent materials like coatings down to 2 microns. Or even as thin as 10 nanometers using our reflectometer for thin film analysis. With just a few clicks, you can easily analyze thickness and or perform a feature detection to identify contours and more.

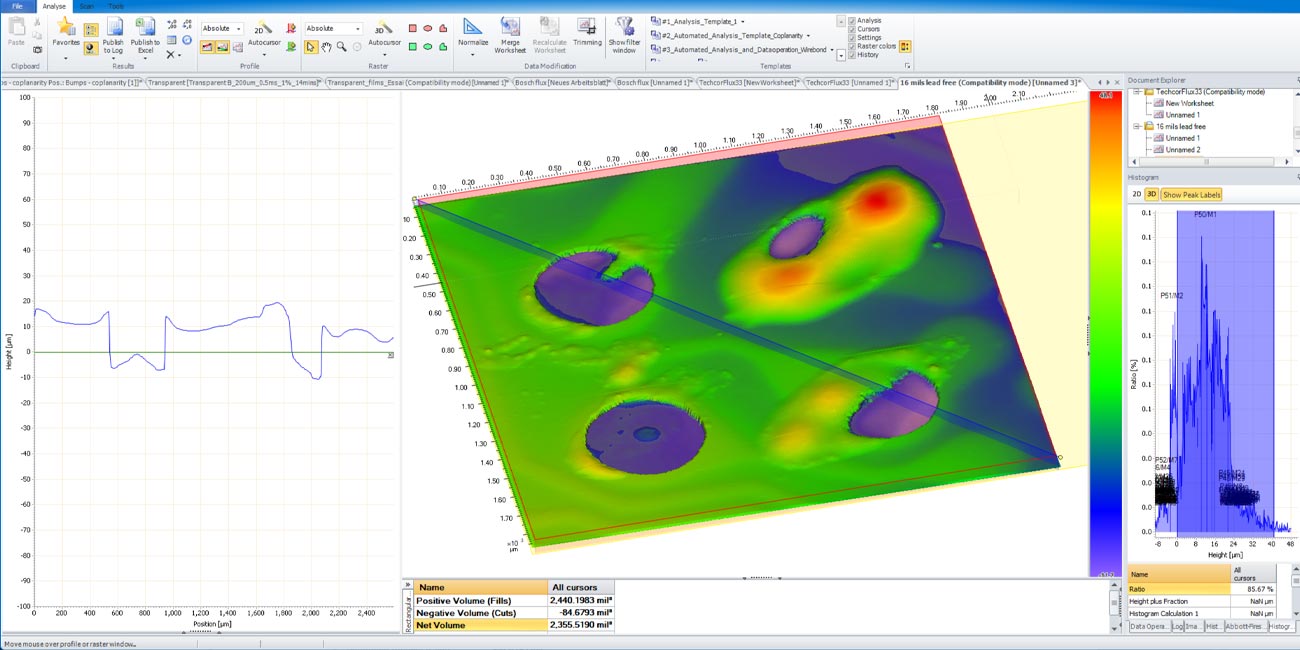

Volume

Measure the volume as a net result from fills (positive) or cuts (negative) to achieve a comprehensive understanding of material distribution.

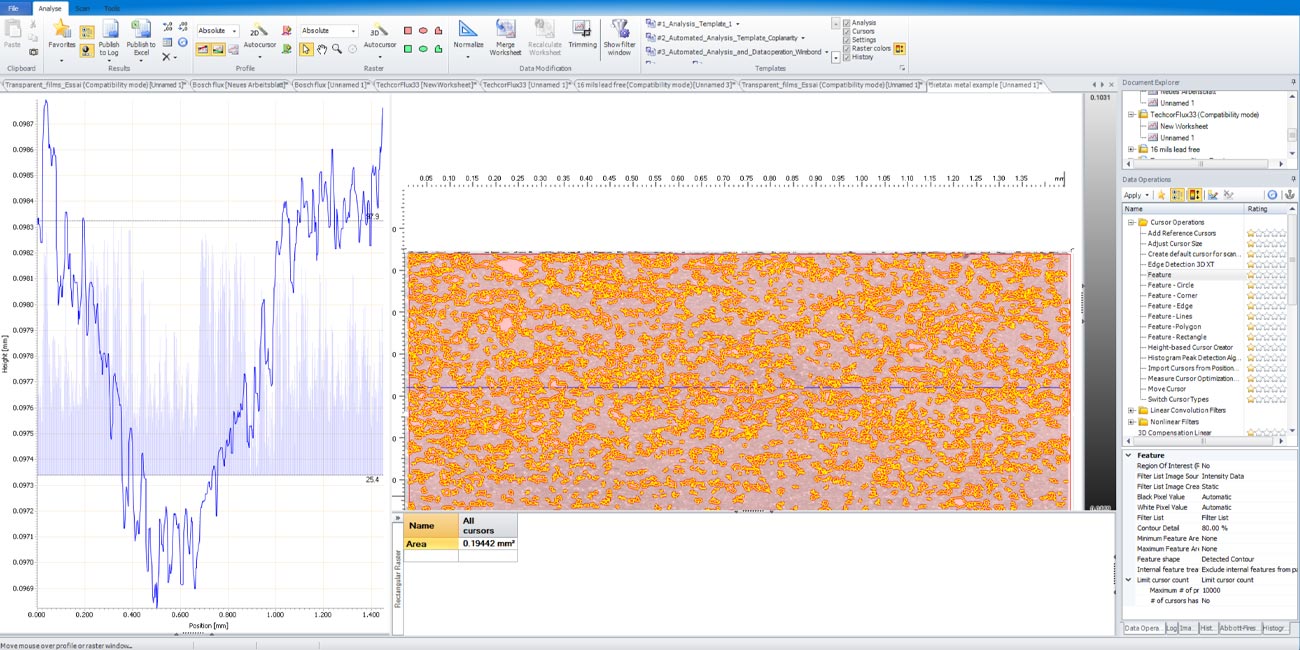

Area

Easily analyze areas covered with coatings using adjustable filter lists. These easy to create filters can automatically identify regions based on either height or intensity data of the product materials.

Automate your Transparent Films & Coatings measurements with ASCAN

Do you have question about your Transparent Films & Coatings measurements?

Non-Contact Measurement

We offer a wide range of sensor technologies designed to meet your unique requirements, including the option for multi-sensor configurations within a single system. For transparent measurements, chromatic confocal technology is often the most versatile and effective solution.

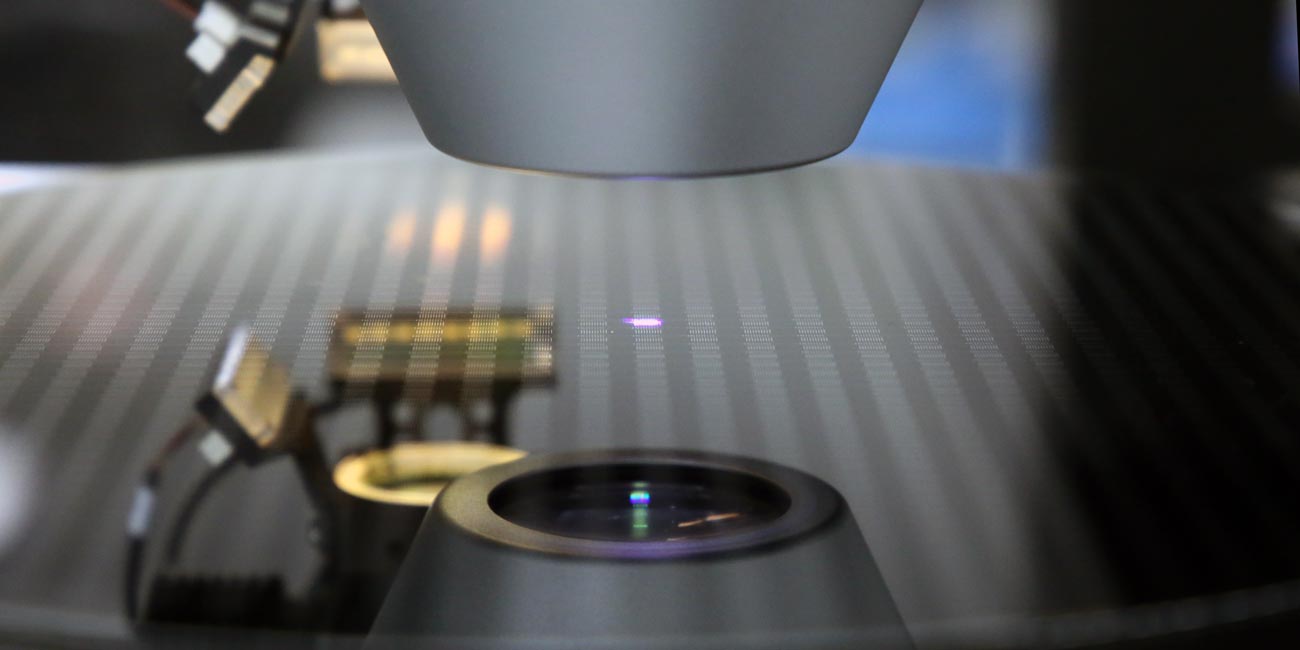

Chromatic Confocal

Measure transparent layers for height or thickness with high-speed chromatic confocal sensor technology, capable of capturing from 2,000 up to 36 million single measurement points per second. With height measurement resolutions as fine as 3 nanometers and thickness measurements in down to micrometers, this technology is a true all-rounder.

Interferometer

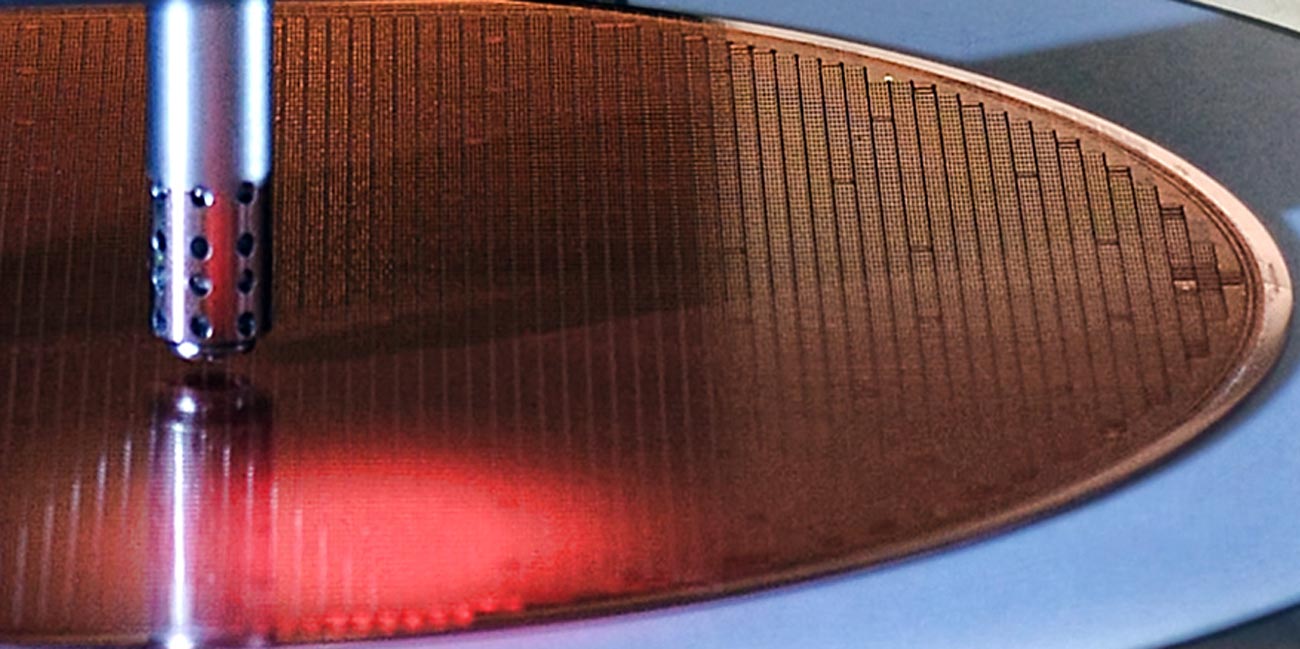

For measuring the thickness of not just transparent layers but also materials that are transparent to infrared light, such as silicon, the infrared interferometer is the ideal solution. It offers resolutions down to 1 nanometer and can capture up to 70,000 measurement points per second.

Other Applications

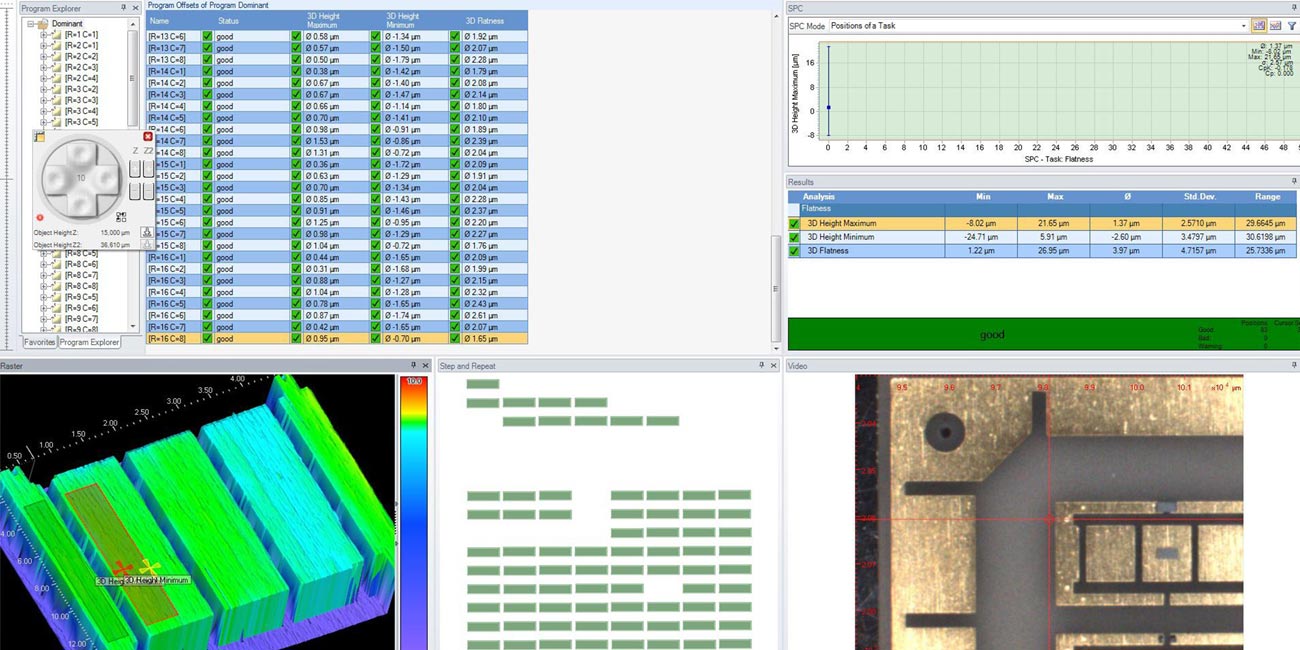

Measure Flatness, Bow, Warp and more of substrates, wafer or any other sample.

Measure coplanarity with seating or regression plane, local heights of pins, pads, bumps, connectors and more.

Let's discuss your needs to find the best solution for you.

General

cyberTECHNOLOGIES GmbH

Georg-Kollmannsberger-Straße 3

85386 Eching-Dietersheim

Germany