Total Thickness Variation

Measure and analyze (absolute) thickness, thickness variation (TTV, LTV) and compare top to bottom surface of your products and samples.

Thickness one or double-sided

Measure and analyze thickness with single-sided systems for materials like glass or silicon or use our double-sided systems for comprehensive analysis on almost all materials.

Thickness Analysis

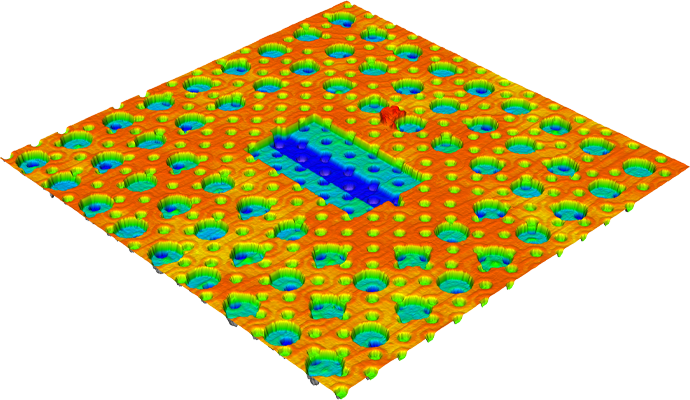

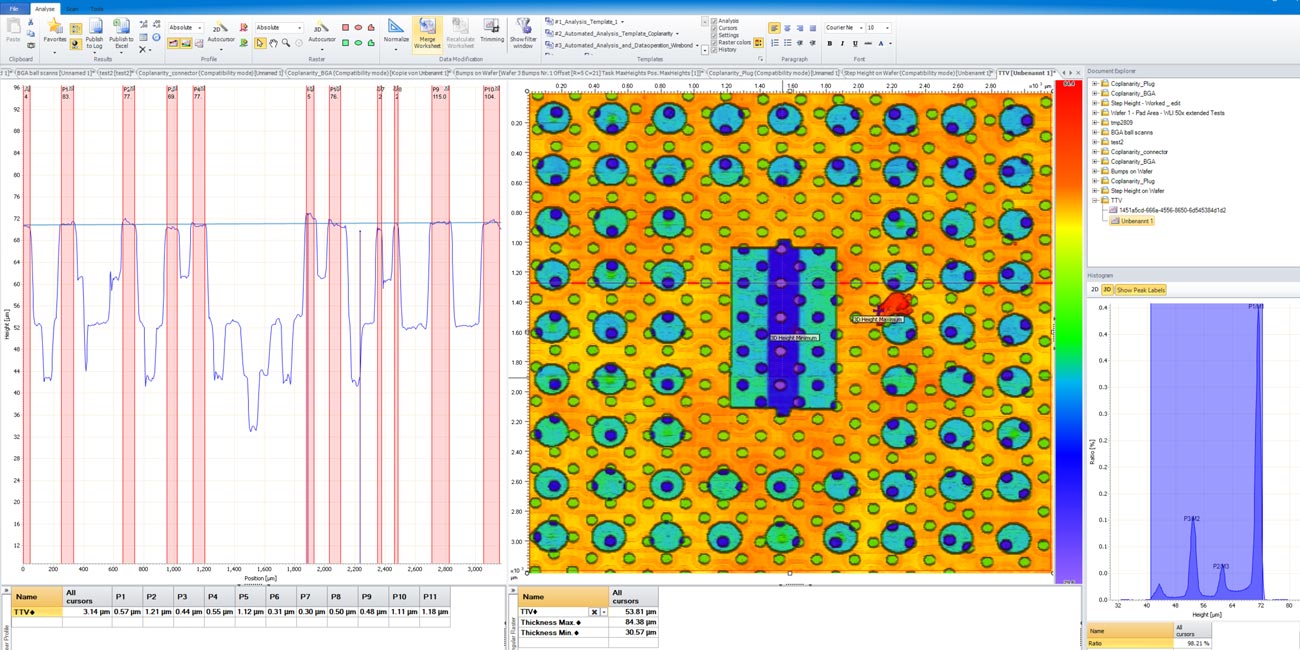

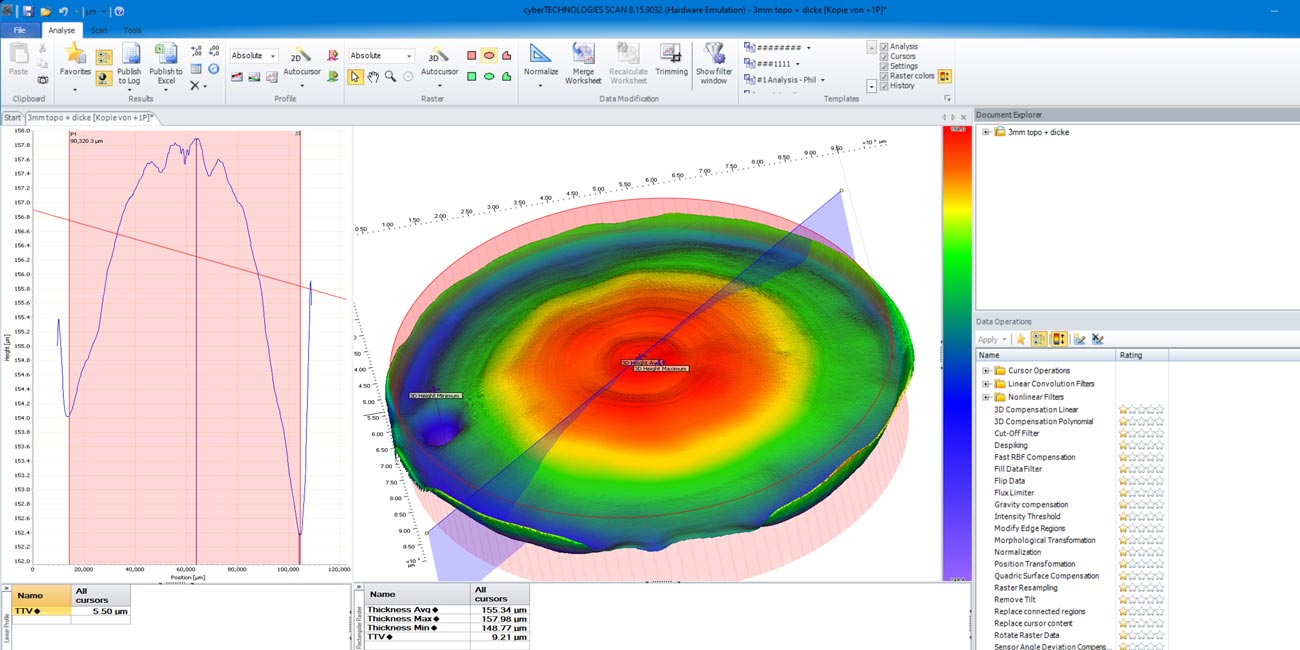

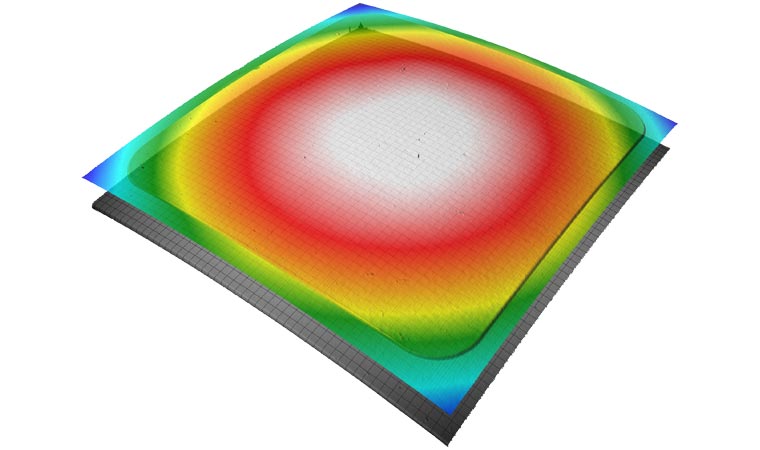

3D Thickness (TTV / LTV)

Measure your samples in 3D of sizes up to 600 x 600 mm² to analyze absolute thickness (average, maximum, minimum) and thickness variations (TTV, LTV) down to sub-micron accuracy.

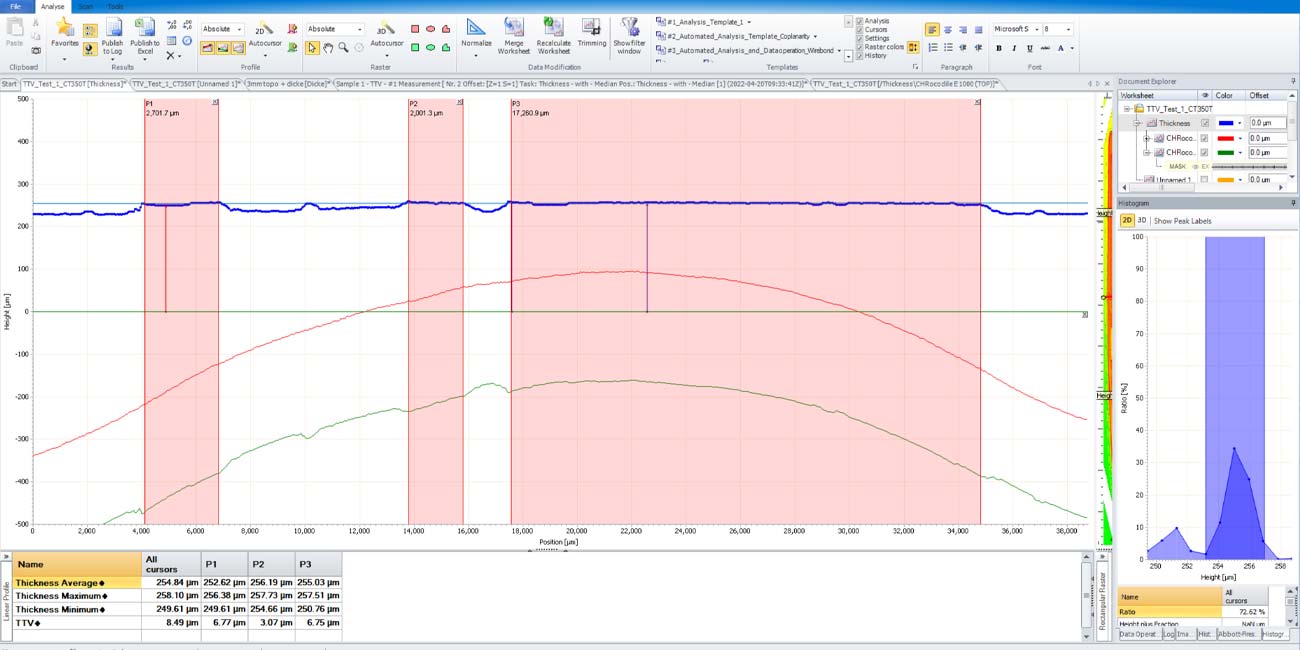

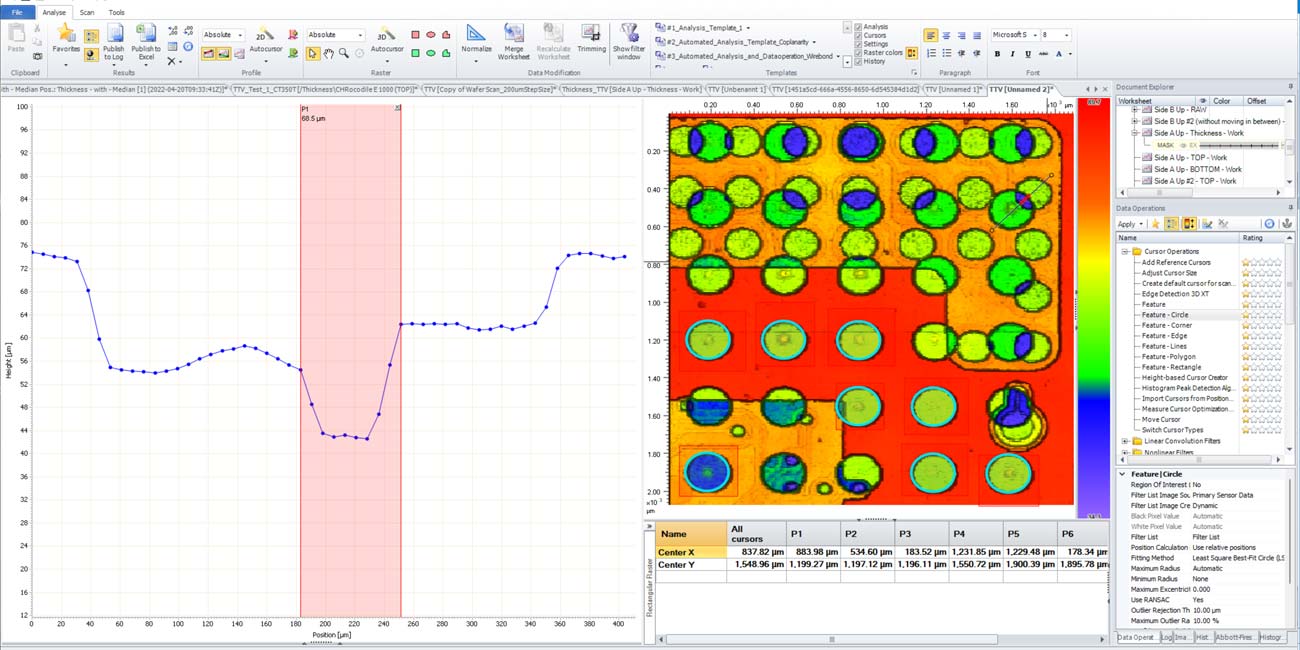

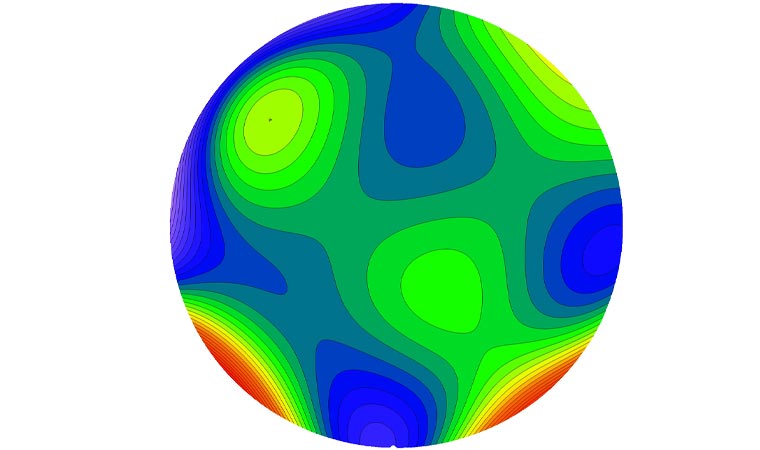

2D Thickness

Perform fast 2D TTV measurements enabling you to analyze both the thickness (blue profile) as well as the detailed structure of the top (red profile) and bottom (green profile) surfaces in a single scan.

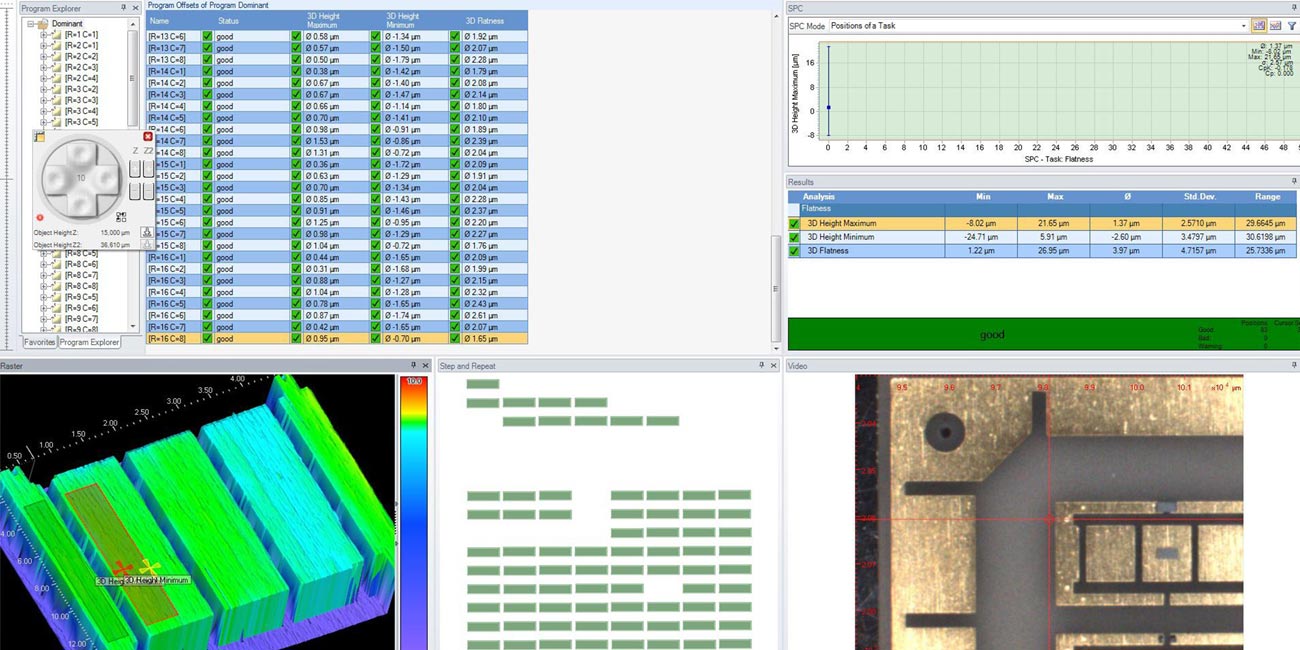

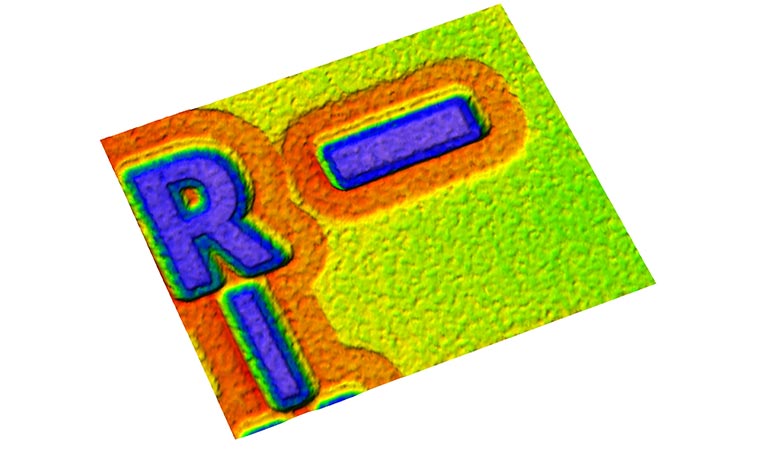

Positions (top to bottom surface)

Accurately verify the positions of features and structures with automated feature detection on both the top and bottom sides of your product, capturing alignment and orientation in a single scan. Use automated programs with ASCAN to confirm that any offsets remain within specified tolerances.

Automate your Total Thickness Variation measurements with ASCAN

Do you have question about your Total Thickness Variation measurements?

Non-Contact Thickness Measurement

The CT-system offer versatile thickness measurement capabilities, providing options for single-sided or double-sided measurements that include detailed data from both the top and bottom surfaces.

Chromatic Confocal

Measure absolute thickness, thickness variations (TTV, LTV) and both top and bottom surfaces on almost all materials. Thanks to double-sided chromatic confocal sensors, our T-systems delivers sub-micron level accuracy. For high-speed applications line sensors are available, measuring up to 1 million data points per second.

Interferometer

System equipped with an infrared interferometer can measure the thickness of materials transparent to infrared light, such as glass or silicon. Achieving z-resolutions down to 1 nanometer with measurement speeds of up to 70,000 points per second.

Examples

Our metrology systems are designed to measure thickness across a diverse range of products and samples.

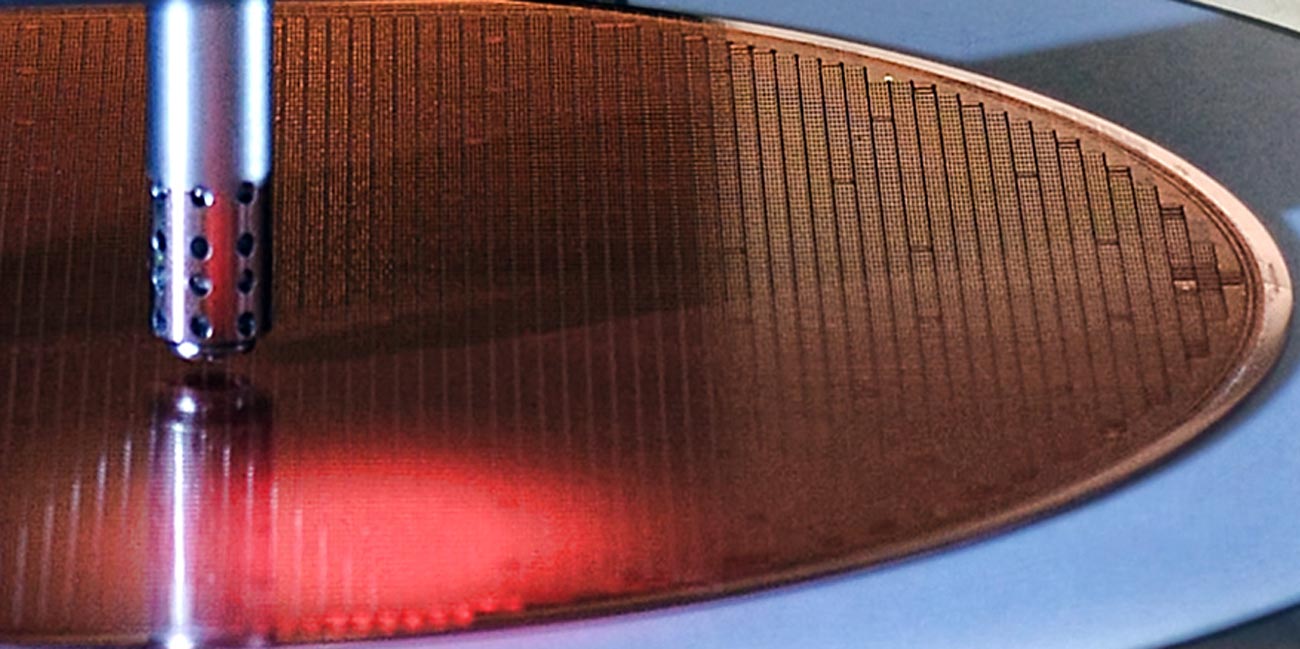

Fuel Cell

Measurement of double-sided waviness, parallelism, thickness and thickness variation with sub-micron accuracy.

Silicon Wafer

Non-Transparent Foil

Measurement of a non-transparent foil to identify positions and detect thickness variation for subsequent production steps.

Other Applications

Measure Flatness, Bow, Warp and more of substrates, wafer or any other sample.

Measure coplanarity with seating or regression plane, local heights of pins, pads, bumps, connectors and more.

Let's discuss your needs to find the best solution for you.

General

cyberTECHNOLOGIES GmbH

Georg-Kollmannsberger-Straße 3

85386 Eching-Dietersheim

Germany