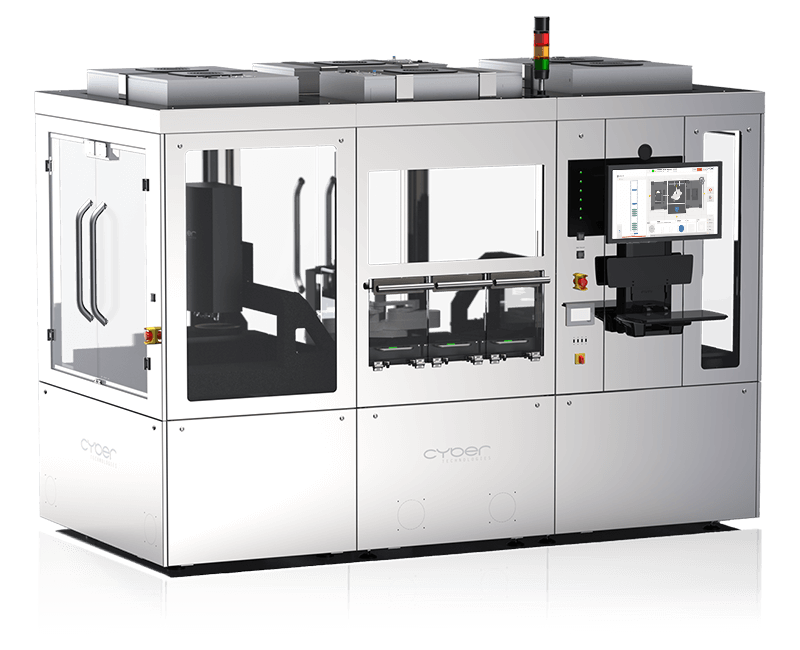

AL 200D

High-Throughput Wafer Metrology

Measurement and Analysis Modes

Fully Automated

including Handling

Measurement Area

up to 2x 250 x 250 mm²

single or double-sided

Use-Case Examples

Step Height, Flatness (Bow, Warpage), Coplanarity (Bumps, Plugs), Thin Film, Lasermarks and many more

Fully Automated

Metrology Cell

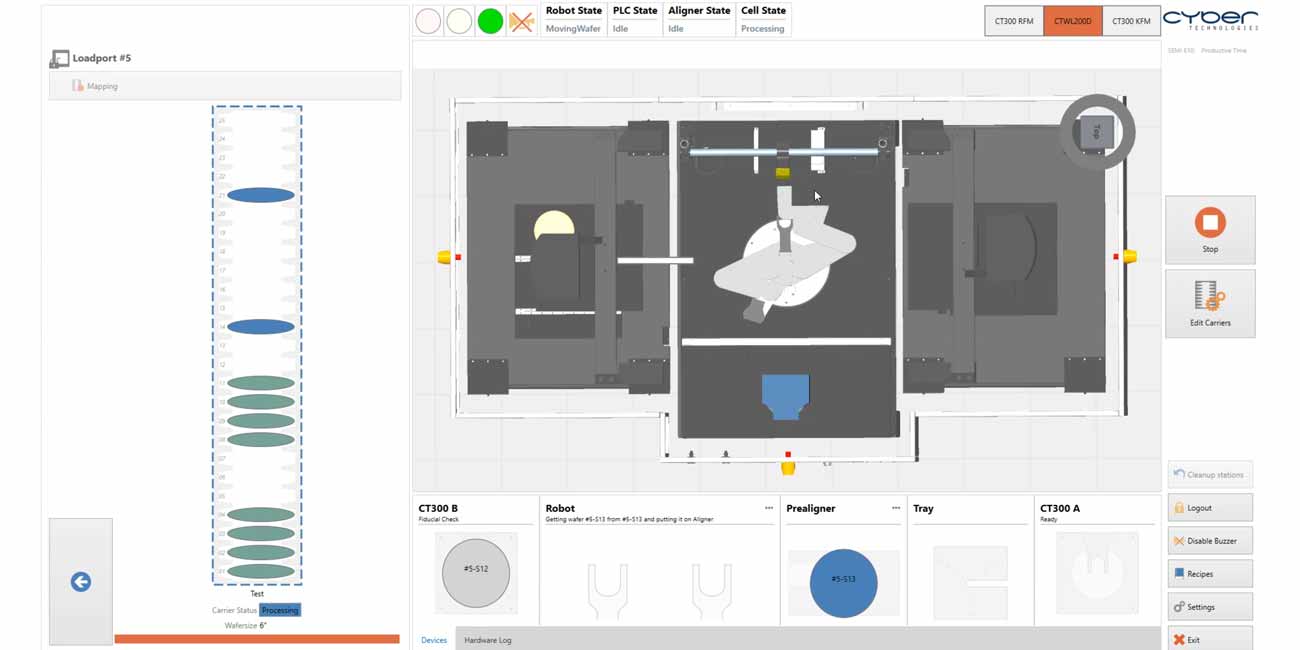

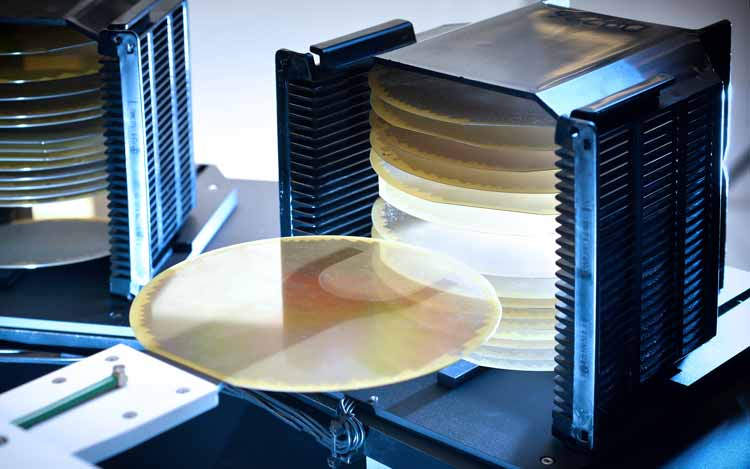

The AL 200D integrates two dockable CT 300 or CT 350T units with a wafer handling system, supporting wafers from 4” to 8”. This design maximizes throughput and can be used for a wide range of front-end applications.

Technology for Throughput

The AL-Series combines a wide range of optical sensors technologies with handling system. Whether in automated front-end environments or specialized setups, the AL-Series stands out for its versatility, reliability, and capacity to deliver enhanced performance.

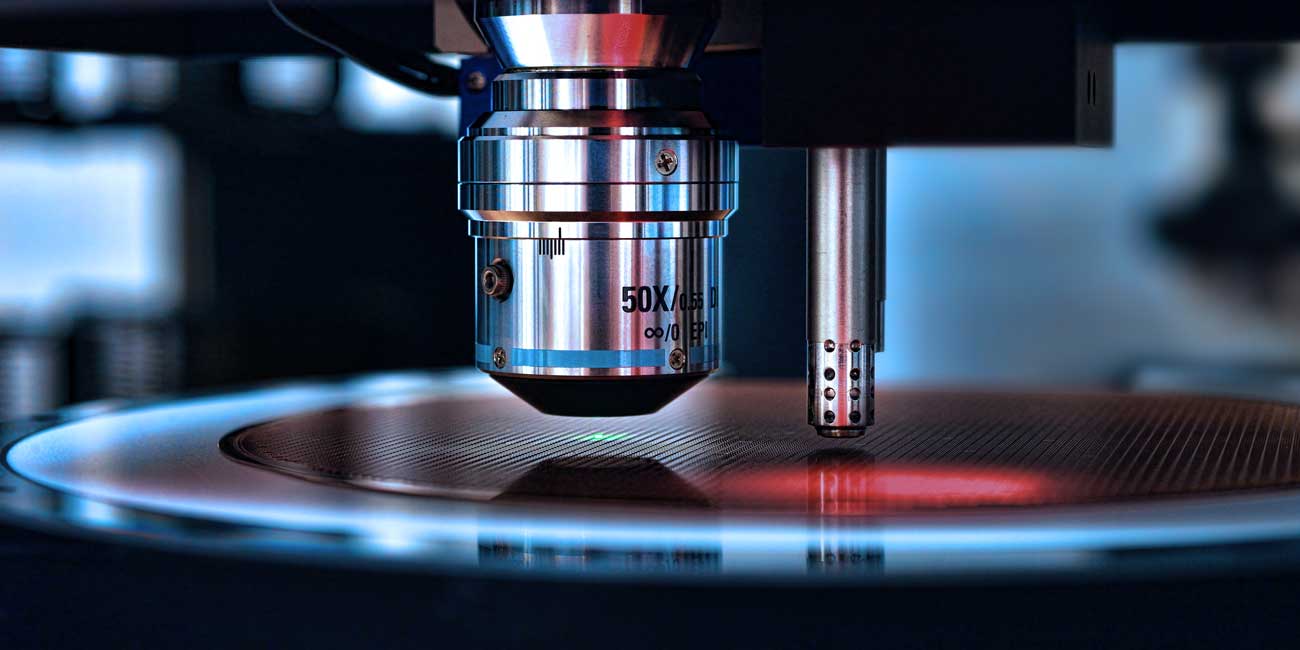

For a wide range of applications in production. Choose from five optical sensor technologies for high-resolution down to 0.1 nanometer or high-speed measurements with up to 36 million datapoints per second. Add great flexibility with a combination of multiple sensors and objectives in one single metrology cell.

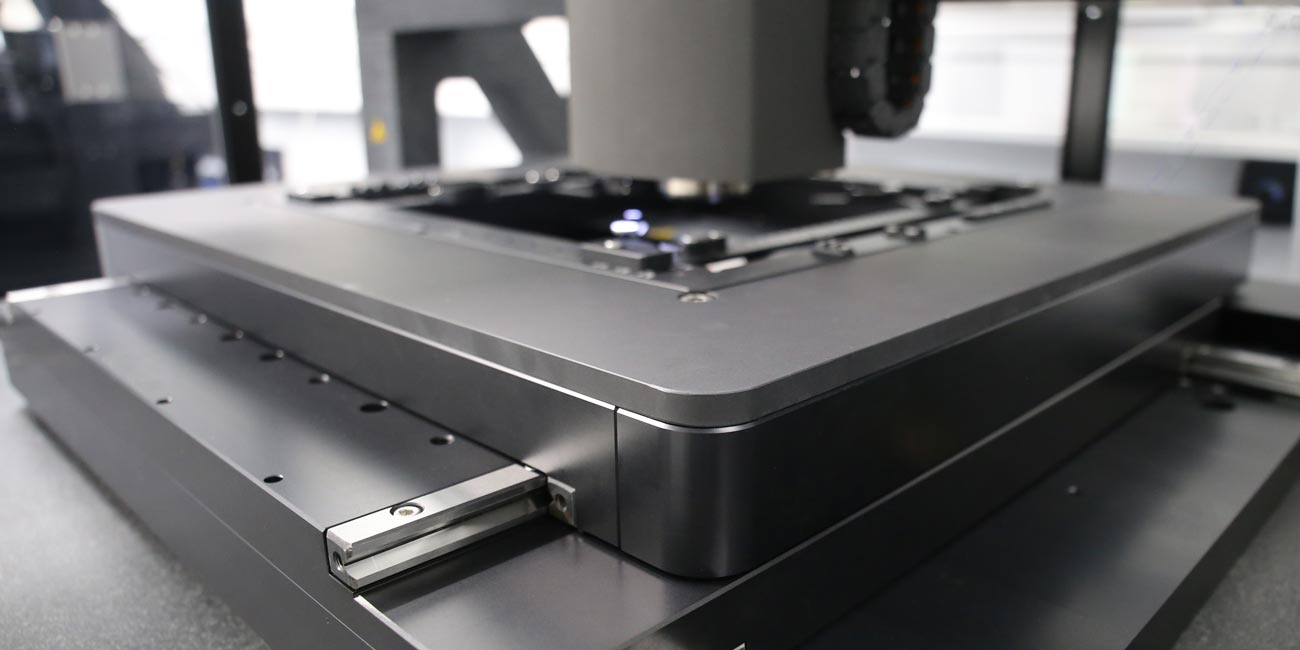

Precise lateral movement on a measurement area of up to 250 x 250 mm². The XY stage, available for single-sided or double-sided measurements, combined with a 50 Nm encoder, ensures pinpoint accuracy for every measurement. Enabling precise positioning and detailed lateral measurements of features. Optionally extend the stage with a lift-pin vacuum chuck or customized interface.

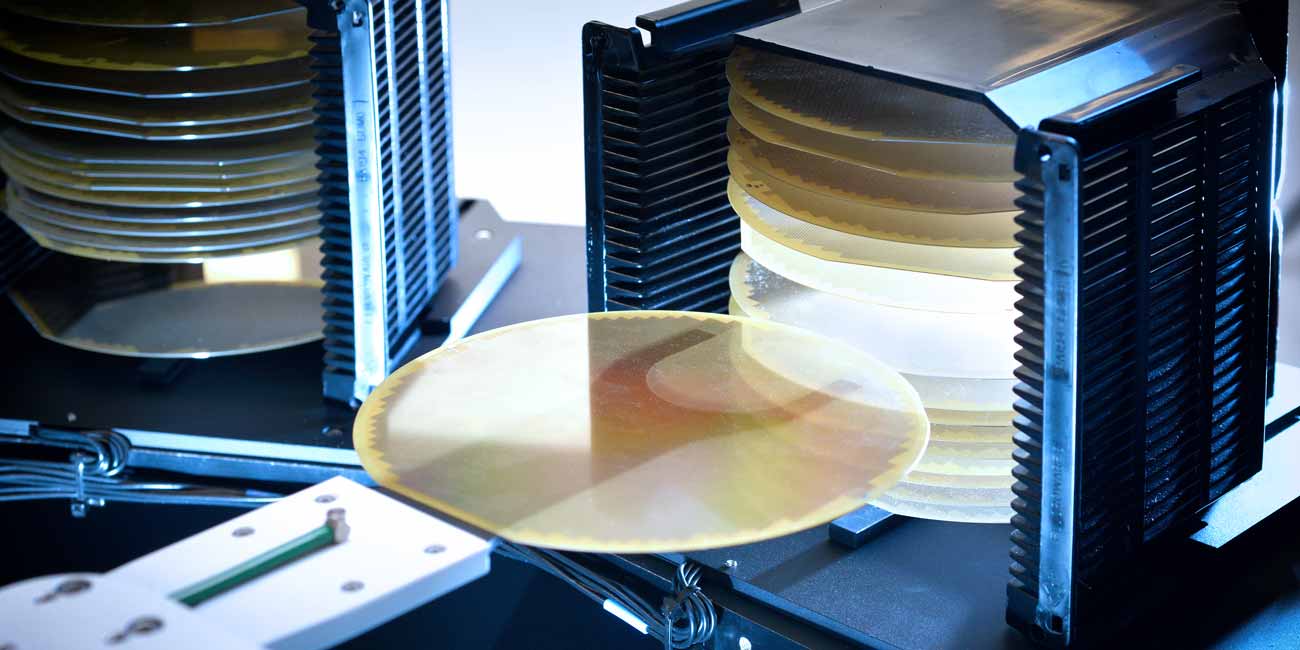

The automated wafer handling system, available with single or dual-arm configurations, can be customized with various endeffectors to suit your specific needs. It also includes wafer prealignment and cassette mapping, ensuring precise processing from the start.

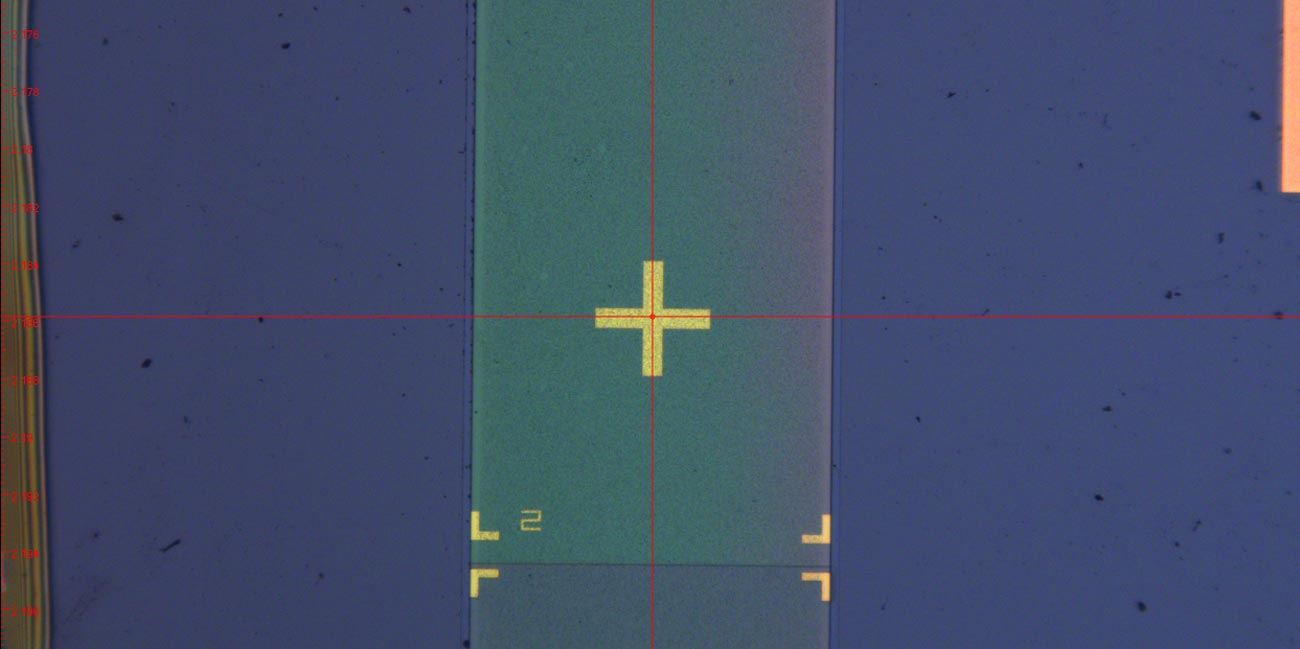

Focus on what matters. The system features a built-in camera with multiple magnification options, allowing you to easily navigate on your samples or choose the sensor’s scanning area in live view. Additionally, the camera enables quick and automated fiducial alignment.

Available Sensors

Flexible high-speed measurements on almost any material with a z-resolution down to 3 nm.

Thickness measurement with a resolution down to 1 nm.

Measure step heights or features with a z-resolution down to 1 nm.

With a z-resolution of down to 0.1 nm for smooth surfaces or smallest (step) heights.

Fast and high-accurate thin film measurement down to 10 nm.

For precise and fast position and lateral measurements with up to 235 MP.

Interested in a configuration of the AL 200D?

Sophisticated Software

Application Examples

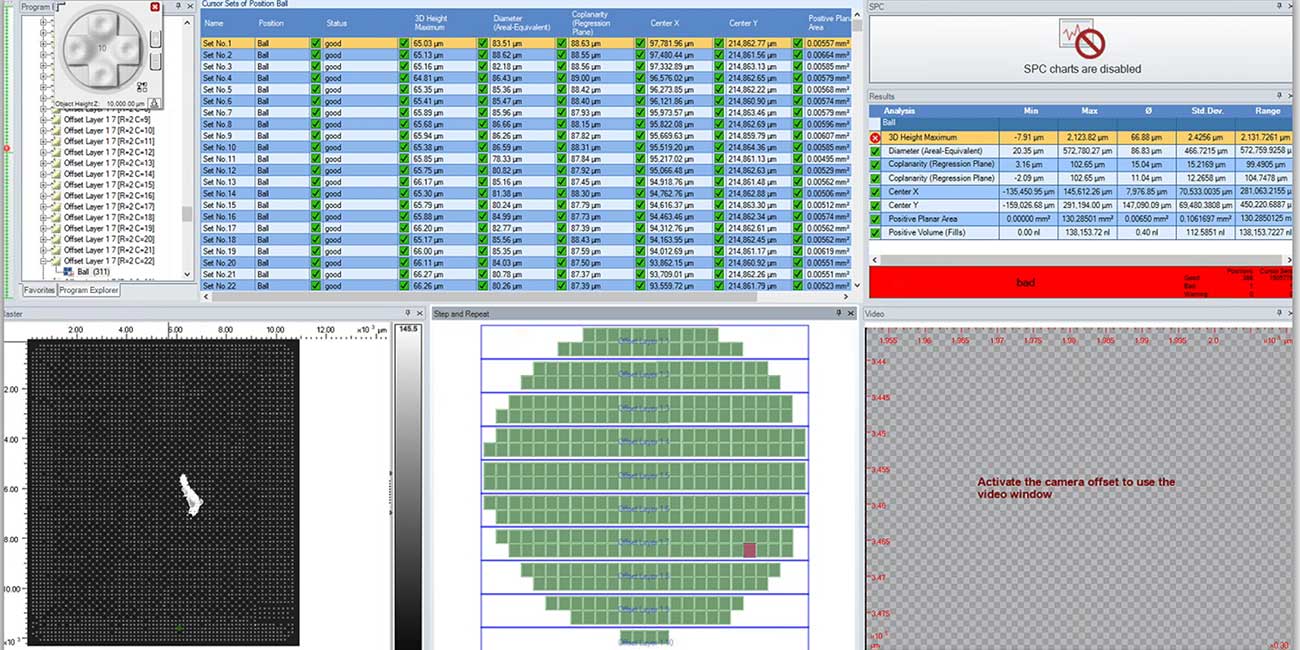

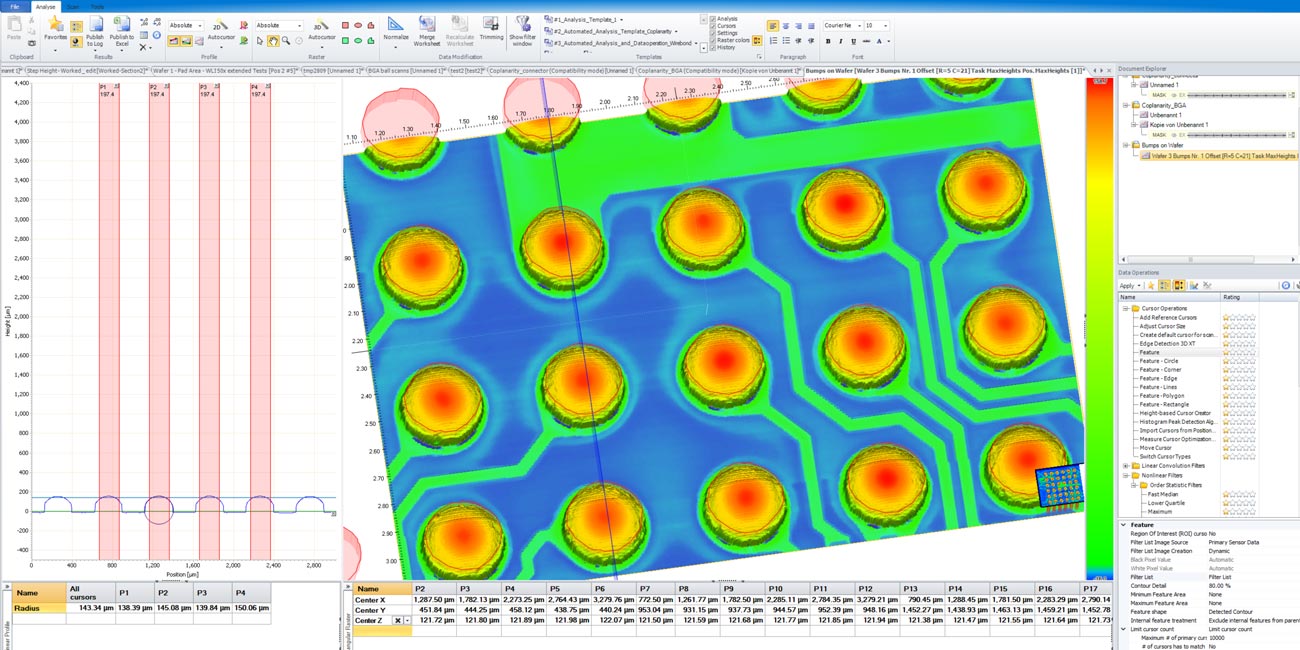

The adaptable multi-sensor metrology cell allows it to be customized to support a wide range of applications. It enables precise quality control, automated sample handling, measurement and fast analysis. Delivering reliable performance for each unique need. This flexibility makes it an ideal solution for any application demanding high-resolution metrology and operational versatility.

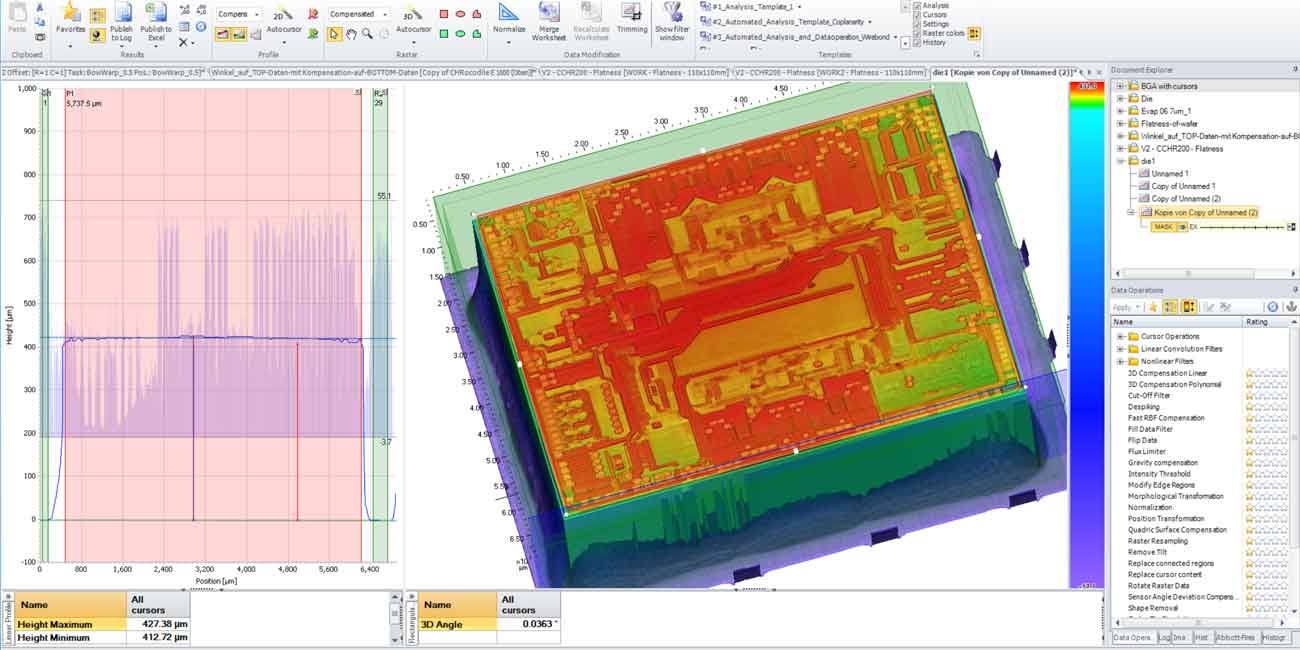

Height, Angle, Die Tilt and more

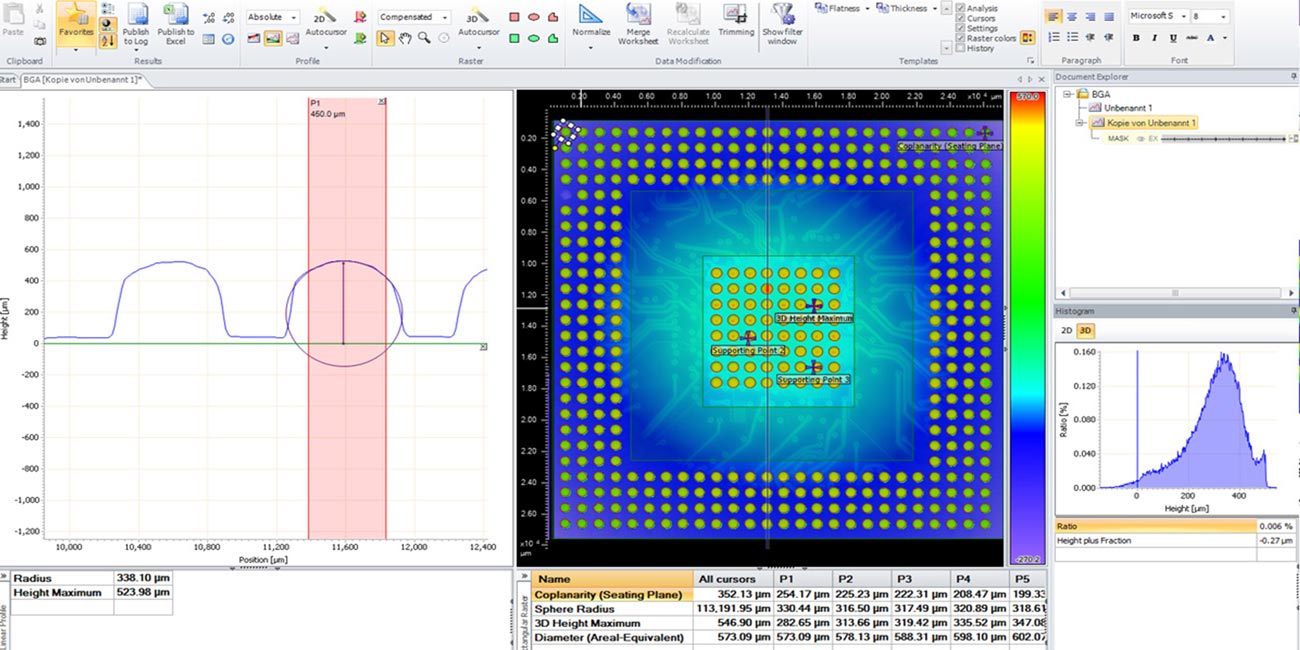

Coplanarity

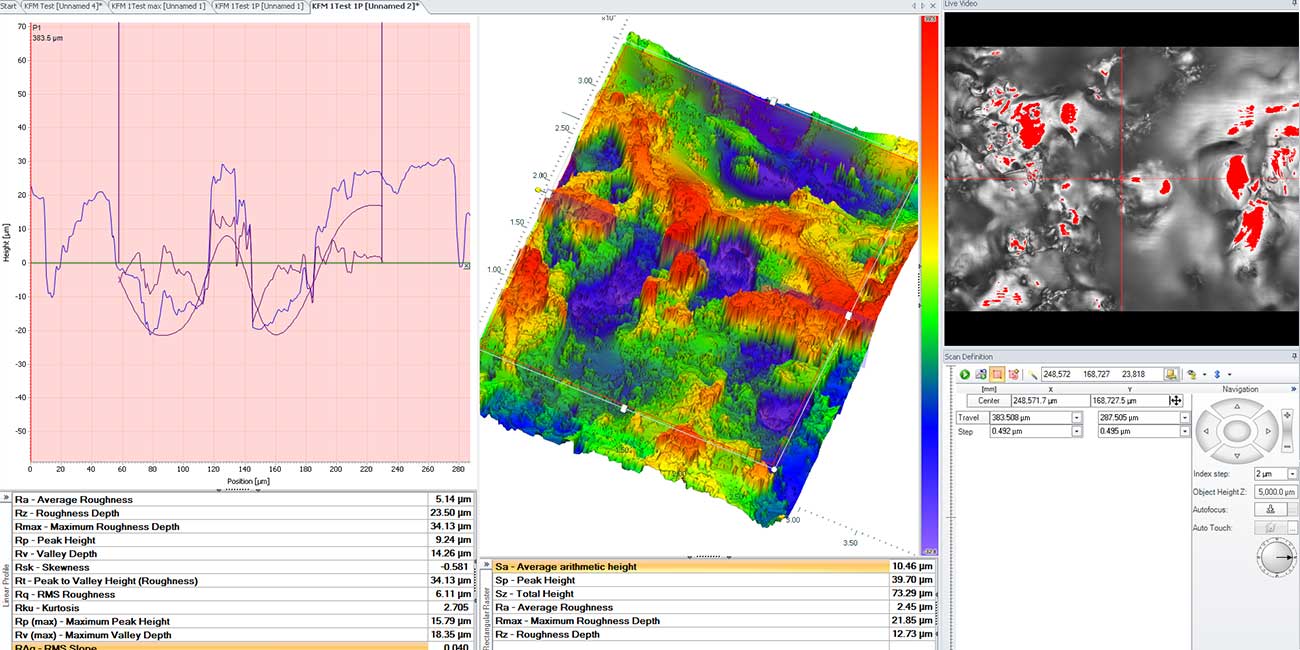

Roughness

Options

The modular design of the AL-series allows for seamless expansion with a variety of upgrade options. Here’s a quick glimpse of what you can add to enhance your system’s capabilities.

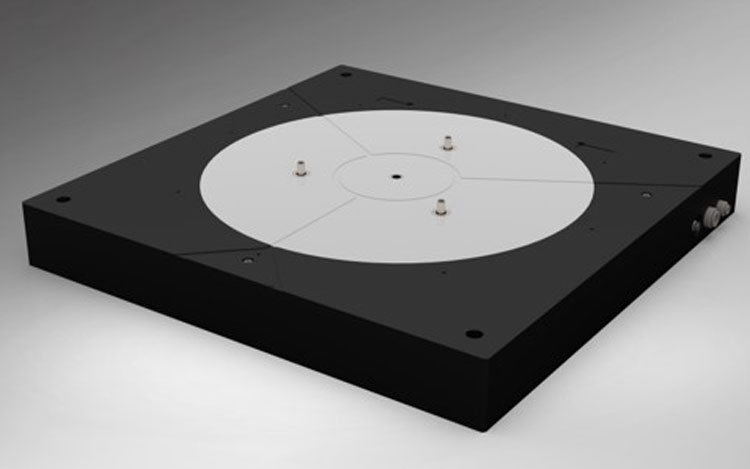

Lift-Pin Chuck

Additional Magazin Slot

Expand your system with additional magazine slots, allowing you to process a higher volume of wafers without the constant interruption of loading and unloading. This upgrade maximizes efficiency and streamlines your wafer handling operations.

Calibration Targtes

A broad selection of calibration targets that can be directly integrated into the system, enabling a fully automated calibration and certification process.

General

cyberTECHNOLOGIES GmbH

Georg-Kollmannsberger-Straße 3

85386 Eching-Dietersheim

Germany